Menu

There are always process steps in production where one resource serves several tasks or operations at the same time. In a dip tank, for example, several production parts from different jobs can be processed at the same time. In most planning algorithms, however, a 1:1 allocation is assumed, meaning every operation is processed by only one resource at a time. Alternatively, the resource is calculated as infinitive. This leads to inaccuracy in planning and inefficient scheduling results. On the other hand, these "shared resources" are often bottlenecks in the production schedule and especially HMLV manufacturers need to improve their throughput for better on-time delivery. We, therefore, have introduced a new parameter in our production scheduling software just plan it that allows allocating one resource to different operations in parallel. Learn more about it in this blog post.

Let's stay with the example of a dip tank and the situation for the planner who needs to schedule the production. The dip tank has a limited (spatial) capacity but can accommodate production parts of different sizes from different jobs. Using a 1:1 operation to resource allocation ratio in the planning algorithm, only one operation, or let's say one "production part", could be processed into the dip tank. The production schedule becomes inaccurate.

How to solve this problem of exact resource allocation? In just plan it the scheduling algorithm now determine the proportion of a resource's capacity that the operation takes up. Therefore we added a new parameter to the system - the "resource usage level". This sounds complicated, but it is not.

Let's assume that there are 2 different jobs (x and y), in each of which a production part runs through the dip tank. The parts that should be processed there are different sizes. The production part of job x takes up 25% of the dip tank capacity, the production part of job y is 50% of it. So theoretically both can be processed in the dip tank in parallel.

The value 1 in the parameter "resource usage" indicates, that a task uses the full capacity of the resource (note: in just plan it we define an operation as a task). As this is the most common case in production scheduling, this value is entered by default in just plan it.

However, in order to take account of the resource capacity utilization in the case of job x the parameter value of the task "dip tank" for the resource usage is not 1, but 0.25, as it uses 25% of the resource. Job y uses 50% of the resource, so the parameter value is 0.50. This way the scheduling engine can calculate a simultaneous allocation of this "shared resource".

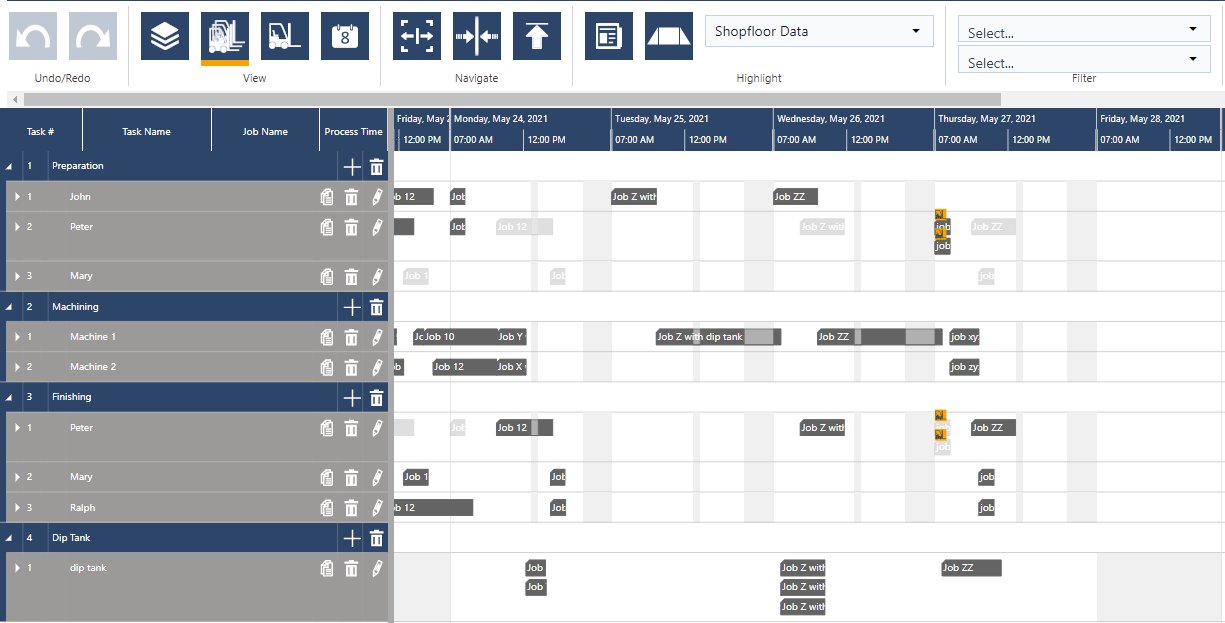

The result you can see here:

The planning board shows job x and y, both with a 4 step production process: preparation, machining, dip tank, finishing. In general, the value of the "resource usage" parameter is 1. Whereas in task "dip tank" of job x the parameter value is 0.25 and in job y 0.50.

In the job order view as well as in the resource view you can see that for job x as well as job y the 2 tasks "dip tank" are scheduled at the same time.

What is the dip tank in one manufacturing company may be a drying oven or an operator who runs several machines simultaneously in another. For all these resources, the allocation of the operation is not 1, but the corresponding share.

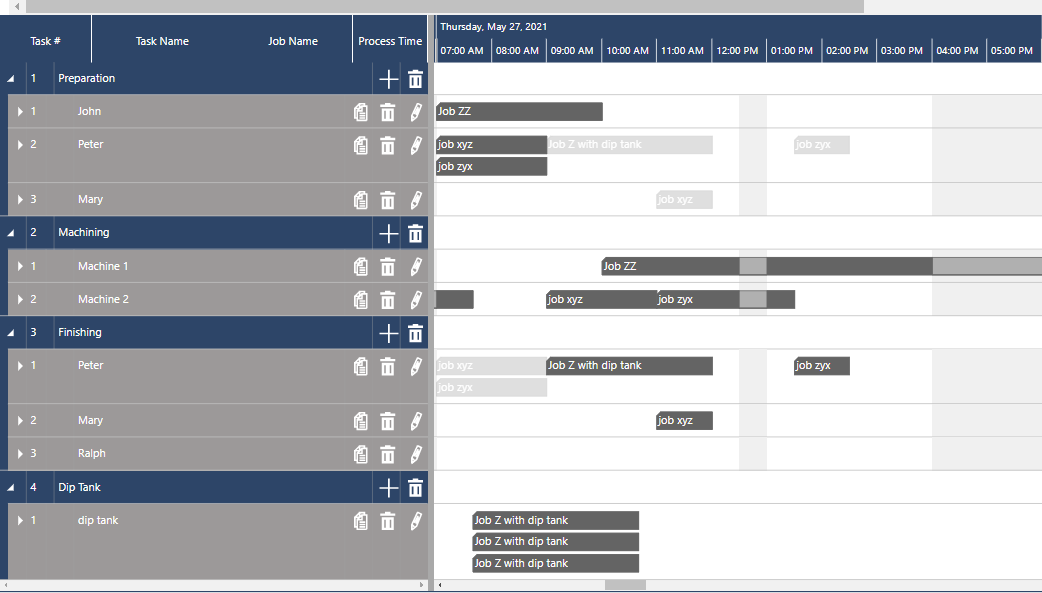

The example below represents the schedule of resource Peter. He is, like many employees at small (HMLV) manufacturers, an allrounder and switches between different workstations. One of his jobs is to control a group of two machines as an operator. We learned from the sample above that in this case, his resource usage level for these tasks is 0.50.

In the screenshot, you can see that Peter is allocated to T010 in job xyz as well as in job zyx at the same time. For the other tasks his resource usage level is 1, so in these cases, he is allocated to one task at a time.

With the new parameter "resource usage" in just plan it the resources are allocated according to their real usage and the schedule is accurately calculated.

If you now want to learn more about the production scheduling software just plan it and how it can support your production schedule, please make an appointment with one of our scheduling specialists.

July 2021 release of just plan it - new feature: Resource Usage Level

How to combine automatic production scheduling with manual scheduling

30% decrease in WIP with purpose-built software for HMLV manufacturer

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Product news

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think