How to improve on-time deliveries, increase throughput

and stop the constant fire-fighting with visual job shop scheduling.

;-)

This is a hands-on resource for all owners of job shops who struggle with keeping delivery times, lack transparency of what is happening on the shop floor, suffer from constant fire-fighting and sense that they should solve "that scheduling thing".

It is also meant to help operations managers and production planners working in a job shop who are tasked with running the shop smoother by introducing proper scheduling techniques.

Last, but not least - it for everybody who is just curious about visual job shop scheduling.

Enjoy reading this guide ;-)

The backbone of most Western economies is mid-sized organizations. Especially in Europe and Northern America, SMB manufacturing companies have been playing a crucial role over the past decades. You can state that the smaller the manufacturing company is, the higher the likelihood that it is any sort of a job shop.

When we speak about a job shop, we mean a manufacturing company that produces small batches of a variety of custom products. They are also referred to as high-mix, low-volume manufacturer. Job shops are usually businesses that perform custom parts for other businesses. Typically, each product produced requires a unique set-up and sequencing of process steps.

Due to the nature of being a customer-driven make-to-order business with a high variety and low batch sizes (and hence less repeatability), many jobs describe themselves as “being in constant chaos and permanent fire-fighting”.

Scheduling is a proven strategy to master this chaos and to stop this fire-fighting.

However, job shop scheduling is a broad topic. Indeed, it is also subject to numerous academic research papers and studies. As insightful this academic research is, as small is its use for job shop owners and operations managers who need to get their arms around scheduling.

However, job shop scheduling is a broad topic. Indeed, it is also subject to numerous academic research papers and studies. As insightful this academic research is, as small is its use for job shop owners and operations managers who need to get their arms around scheduling.

Due to being in a constant fire-fighting, many job shop owners not only lack the time to digest all this academic research. Even worse: the academic research regularly lacks practical advice and hands-on methods to apply.

This guide is meant to cut this Gordian knot.

It is meant to provide insights gained from academic studies … in a manner that is consumable for people running a shop, and being in constant fire-fighting.

It is also meant to guide how shop owners can turn the theory into practical, day-to-day actions.

So, let’s get on the same page. Let’s make sure that you and we have the same understanding of what job shop scheduling is.

This all starts with having the same view on what a job shop is, and what makes a job shop specific compared to other types of manufacturing companies.

The strongest characteristic that unites all job shops we have been working with is that change is the only constant. Here is why:

The strongest characteristic that unites all job shops we have been working with is that change is the only constant. Here is why:

Overall, a job shop can be characterized as a high-mix, low-volume manufacturer facing a highly volatile, ever-changing, and, not uncommonly, chaotic environment.

To master this “chaos” and the existent uncertainty in a job shop it is essential to introduce some kind of structure, visualization, and planning tools. But precisely because of the pervasive volatility, implementing a proper job shop schedule presents manufacturers with more than one challenge:

To master this “chaos” and the existent uncertainty in a job shop it is essential to introduce some kind of structure, visualization, and planning tools. But precisely because of the pervasive volatility, implementing a proper job shop schedule presents manufacturers with more than one challenge:

1. How can a job shop manufacturer introduce a structured plan while what job shops lack most is a structure?

2. How can one properly account for sudden and frequent changes?

3. How can one optimize and improve operations when forms of routines and forecasts are rare?

And these challenges are just the tip of the iceberg. However, when being aware of some important insights, understanding the underlying concepts and models, and applying some helpful tools, chances are high that job shops can master this challenge.

Those who master this challenge are most likely to run smoother and to prosper more than job shops that do not schedule but just react to what is happening.

This is why you came to this guide, and this is why we encourage you to continue readings.

The job shop scheduling problem also can be seen as a sequencing problem. If you want to solve it, you have to deal with a few constraints. Here is a minimum set of these:

The ultimate goal is to meet delivery times while making the best use of the available resources.

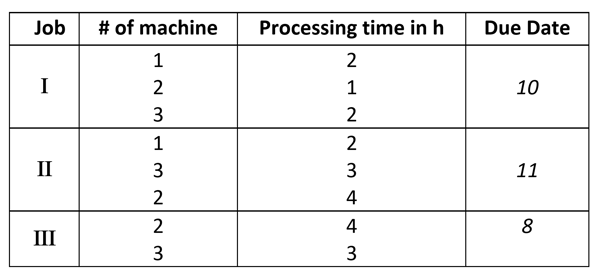

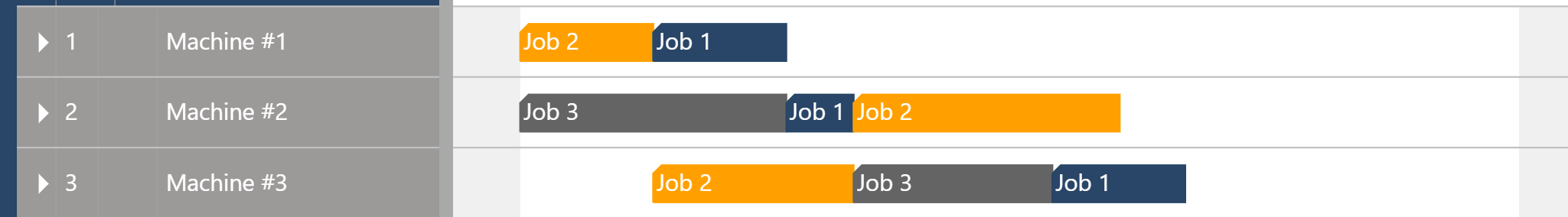

Here is an example of just this sequencing challenge. It is based on the assumption of a stable environment. Hence, the other challenges outlined above (frequent change) are not yet part of this example. Let’s assume we have three job productions to allocate to three machines (e.g.: job III first requires 4 hours of machine 2 and afterward 3 hours of machine 3. Further, the job should be completed after 8 hours).

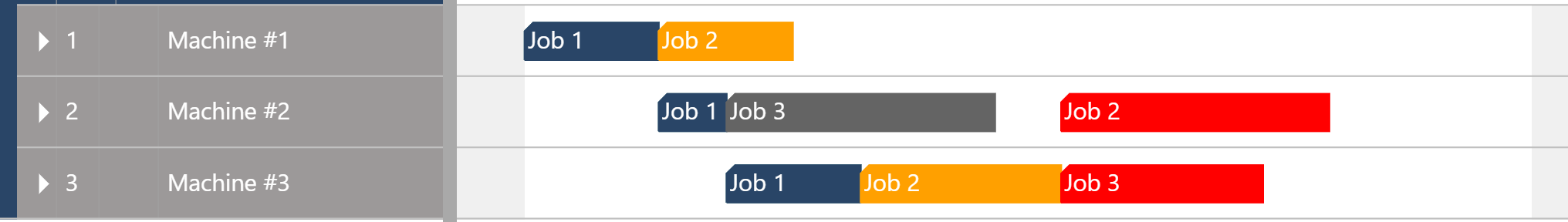

The first scenario below represents a non-ideal solution to the problem. The scheduler first allocated every task of job I, then every task for job II and finally every task of job III without changing previously made allocations. As a result, job II and job III cannot be delivered on time.

Now, let’s look at a better solution. Every time a new job order comes in, the scheduler adjusts the current schedule with keeping delivery dates in mind. Here is how to best solve the puzzle:

Now you might rightfully say that you could've easily solved the above on a whiteboard, with Excel etc.

However, here is what is really typical for a job shop.

This is job shop scheduling: order prioritization, order sequencing, machine scheduling, resource scheduling ... multiple times a day.

In essence, scheduling is a process of matching supply and demand.

In that particular case, it matches the demand for a manufacturer’s capacities resulting from the customer orders with the available capacity (i.e. the supply of capacity). When done properly, delivery times are met and resources are used effectively.

A job shop that falls short on proper scheduling runs severe risks:

A job shop that falls short on proper scheduling runs severe risks:

Avoiding these risks makes job shop scheduling so important.

On the flip side of the risks of having no proper scheduling system in place are the benefits of having one. We will shed more light on this later, but here is already an overview of them:

Proper scheduling provides visibility and transparency. This is meant for all work orders, but also for machine capacities, due dates, idle times, shop floor progress, production dependencies, and much more.

Proper scheduling provides visibility and transparency. This is meant for all work orders, but also for machine capacities, due dates, idle times, shop floor progress, production dependencies, and much more. By now, you should have noticed that having a proper scheduling tool in place is essential.

By now, you should have noticed that having a proper scheduling tool in place is essential.

However, if you want to achieve scheduling success, just a tool will not do the job.

You should go for a tool that adds a little, but a highly valuable element to scheduling.

And this is visual scheduling.

Click here if you want to learn all basics of visual job shop scheduling.

You heard the saying that a picture is worth a thousand words. You also applied it many times in your life. Think traffic lights, brand logos, or emojis on your smartphone.

You heard the saying that a picture is worth a thousand words. You also applied it many times in your life. Think traffic lights, brand logos, or emojis on your smartphone.

Communicating by using gestures, signs or images is the most effective approach of sharing knowledge as the human brain processes information through images.

In fact, around 50 percent of our brain is busy with visual processing.

This insight cannot be ignored when it comes to understanding the success factors of job shop scheduling.

Visual job shop scheduling uniquely combines the best of both worlds. It brings together

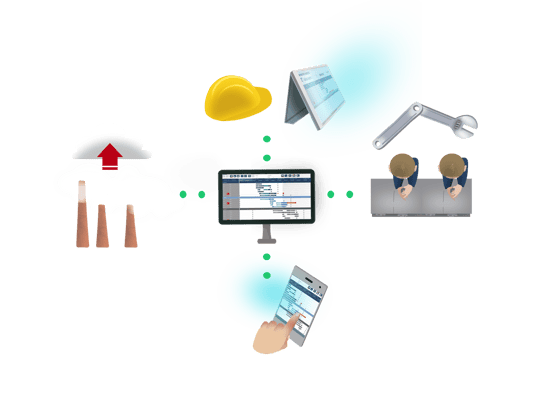

As such, it predominantly provides transparency and lets the scheduler understand the complex scheduling mechanisms that happen behind the scenes.

That way, visual job shop scheduling puts the user into the forefront of everything, and the scheduler and planner into the driver’s seat.

We have hundreds of customers, who over the years have scheduled hundreds of thousands of jobs with just plan it. As a consequence, over time we scheduled millions of tasks (always taking into account any given condition and restriction).

This job shop scheduling usage data is an invaluable source of insight for us and helped us to derive both job shop best practices and machine shop best practices.

When it comes to job shop scheduling best practices, we learned that it is useful to differentiate the phase of selecting a job shop scheduling tool and the phase of actually using it. Here is a detailed blog post exactly on this. It provides you with seven tips on how to achieve your scheduling goals in a high-mix, low-volume shop.

Consequently, we present our job shop scheduling best practices along those two dimensions:

Before we drill into the individual best practices, here is the one golden advice that we like to give (and it had been said by Voltaire back in the days).

Perfect is the enemy of good.

Do not search for a perfect tool. Resist the temptation (which might even kill you). Go for an appropriate tool. Let’s break this down into three best practices to apply when selecting a job shop scheduling tool.

You are a job shop. The only constant you have is constant change. Hence, your data will never be precise and exact.

Now, let’s think about what “optimization” means. Optimizations require algorithms. Algorithms require clear and stable rules, and they require exact data. Otherwise, you achieve garbage-in, garbage-out.

With going for optimization, you go on the route to fail. Go for something that is made to cope with constant change in your job (and not for something that is silently based on the assumption of stability).

As most job shops face more than 1,000 tasks to schedule at a time, a project-centric planning board that just provides some manual drag and drop won't be appropriate either. The typical combination of the volume of tasks and the velocity of jobs makes pure manual scheduling very hard.

Watch out for a tool that provides effective automatic scheduling. Automatic means: there must be some logic happening in the background, but no optimization.

This logic must be tuned to deal with a high-mix, low-volume business. And it should be made to help you with what matters most: improving on-time deliveries.

We had this before. Job shop scheduling should be visual job shop scheduling. This is not just a best practice, it is a must. No more words to say.

We have seen it so many times: Companies undertake an enormous effort into selecting a job shop scheduling tool. We wish they would do as well when it comes to using it. Hence, we have a piece of golden advice for usage as well. This time, we do not need to quote somebody else.

Job shop scheduling is hard work. You need executive sponsorship, clear responsibilities and routines, routines, and even more routines.

If your CEO and/or the owner of your high-mix, low-volume shop is not behind your attempt to implement proper scheduling – just forget it.

Introducing scheduling is not a one-time investment into buying some software tools. Much more important: it requires ongoing time to work with the software.

Make sure, you have the backing of your manager … and also make sure that your software provides you with some KPIs and statistics to prove the value it delivers.

Yes, scheduling is teamwork. Of course, it requires somebody to build, manage, and run the schedule. Typically, this is the production planner or the operations manager.

However, a great schedule (and this is something you also should look for when investigating scheduling tools) also can get easily updated. This update does not just mean to add new jobs. This is part of the planner’s job.

Updating the schedule means also adding actual data from the shop-floor and hence adjusting the schedule in real-time. Providing actual data from the shop-floor no longer is the planner’s job. This is something the operators or foremen should be held accountable for.

Scheduling is no magic pill that you take, and all your griefs vanish instantaneously. Scheduling is an ongoing process. Here is the metaphor that we keep on using:

Scheduling is like a dishwasher. The machine will help you to achieve your target much more productive than the manual option. But you rely on routines to operate it. There must be someone responsible to gather the dirty dishes. Another one is responsible to fill the machine. Then there must be one to select the program and to start it. Finally, the clean dishes need to be put to its origin. Then the same procedure starts again and again.

So, let’s go an get your dishwasher making the ugly work for you. It is up to you to define routines to make that happen.

If you manage to establish routines, which are permanently lived and which become a "natural" part of the daily business, then you will meet your scheduling targets using any appropriate scheduling tool.

Visual job shop scheduling provides high-mix, low-volume manufacturers with a plethora of benefits. We regularly interview our customers what they get from using our software, and they shared with us six tangible job shop scheduling benefits.

Here is a summary of these benefits. Follow the link just provided (https://www.just-plan-it.com/smb-production-scheduling-blog/six-job-shop-scheduling-benefits) if you want to take a deeper dive.

A visual schedule lets you quickly see which jobs are running late, and which jobs are in danger of running late. It also helps you to understand dependencies and to easily spot bottlenecks.

A visual schedule lets you quickly see which jobs are running late, and which jobs are in danger of running late. It also helps you to understand dependencies and to easily spot bottlenecks.

And by the way: understand is the important word here. Transparency enables understanding.

Once you fully understand your schedule, the dependencies, and potential threats, you can easily take countermeasures, and get control of what is happening in your shop.

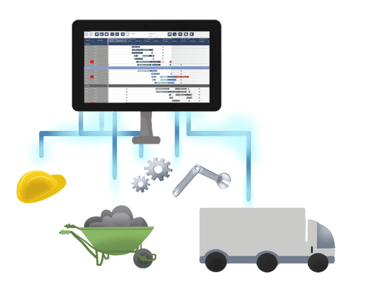

With proper scheduling, new jobs are added to your existing schedule automatically – taking into account finite capacities, your shop calendar, and potential machine downtimes. In the second a new job hits the visual job shop scheduling software, you see the realistic delivery date.

This is what you can communicate with your client. Important is: this is a realistic date.

With this ability to give realistic delivery time commitments, your OTD will skyrocket.

According to Little’s Theorem, there is a direct correlation between the amount of work-in-process and the lead time. The higher the WIP, the longer the lead times.

According to Little’s Theorem, there is a direct correlation between the amount of work-in-process and the lead time. The higher the WIP, the longer the lead times.

How does visual job shop scheduling help?

The answer is transparency. Precisely: visual scheduling lets you easily identify bottlenecks.

This is not trivial as bottlenecks – due to the nature of job shops – keep on changing.

However, once identified, you can apply countermeasures (such as subcontracting) and eliminate bottlenecks, which in your case most likely are just temporary.

With eliminating bottlenecks, you can cut lead times.

If you manage to cut down lead times and if you keep your capacity at the same levels, you manage to get done more in the same amount of time.

Another way of phrasing it: by cutting lead times, you can increase your throughput.

If you combine these four benefits, chances are high that this will fuel revenue growth. Here is why:

In essence, we observe that our customers – as a result of 1 to 4 – feel comfortable taking more orders in. Orders that they would have declined before as they lacked transparency and were in a constant firefight.

Visual job shop scheduling gives you control over what is happening on your shop-floor. You have less fire-fighting, you get fewer distractions from unplanned incidents resulting in big chaos and hence you have less stress.

The fist example is from Paneltech from the UK, and you can read the full Paneltech case study here.

Before using just plan it, Paneltech tried various systems. They ranged from simple spreadsheets to very expensive advanced scheduling software. However, they were not made for make-to-order manufacturers and hence “always had a point of failure” as Ross Larner, Operations Director and Co-Owner, remembers.

The challenge was that people didn’t trust the system and hence did not follow a plan. Constant fire-fighting was the norm and Paneltech needed to set a plan in place that would be stable, which they could trust and which would stop the lack of productivity.

Ross Larner:

“The even bigger, wider issue was that we couldn’t give the customer a firm date on when a job would be done. Or, even worse, whether it wouldn’t be done on time at all.”

In the first month of working with just plan it, Paneltech could run the shop without any overtime. “But nevertheless we delivered all jobs in time. This alone saved us 5,000 Pounds on our payroll”, as Ross remembers.

With just plan it Paneltech has transparency on what is happening on the shop-floor, and is able to make firm delivery time commitments. As everybody works with the same actionable schedule, the amount of fire-fighting and interruptions has significantly decreased.

Ross summarizes:

“We had a 30 to 40% increase in productivity in week one. The return on investment was within 1 or 2 months. As everybody trusts the software, I get less interruptions. This is actually giving me more time to focus on other things to take my business forward to the next level.”

The second example is from CIOvita in South Africa, and you can read the full CIOvita case study here.

Ciovita has been successfully using the apparel-specific ERP system iSync for all financial and administrative processes. However, production scheduling always happened outside the ERP system. For that purpose, Ciovita built a homegrown system with Microsoft Excel relying on a lot of exports and re-imports.

Andrew Gold, CEO of Ciovita concludes:

“This worked for a while, but did not scale with the company’s growth. It was not visual and most importantly, it was not dynamic. In addition to this, a spreadsheet program like Excel misses any drag & drop functionality.”

With the transparency provided just plan it, Ciovita managed to get a better alignment towards production goals. In addition to this, just plan it enables faster and better scheduling decisions resulting in increased on-time deliveries.

Andrew Gold summarizes:

“just plan it helped us most in making sure we deliver on time. We have seen a 25% increase in on-time orders. Most important is: Each department can see the impact their efforts have to keep a job on track.”

By now, you should have learned

Now, it is time to put the theory into practice. What follows is concrete advice, checklists, and to-do lists.

You get concrete action items to apply if you do not just want to be a job shop scheduling theorist, but somebody who successfully applies scheduling to manage and prosper the own shop.

Hey, are you still unsure that you REALLY want to get going with job shop scheduling? Here are three signs that your shop truly needs proper scheduling.

Regard this as a checklist: if at least one of these signs is valid for your shop, do not waste more time. Become concrete. Get it going.

Now.

One thing should be undeniable: whatever approach you take for scheduling, the purpose always is to help you better understand, plan, and manage your production.

One thing should be undeniable: whatever approach you take for scheduling, the purpose always is to help you better understand, plan, and manage your production.

If this is achieved, you gain a lot – as I outlined in the benefits section of this guide in all details. However, there is also a hidden cost associated with scheduling (and I not referring to the cost of purchasing a scheduling tool).

This hidden cost is the cost of updating and maintaining your schedule. With a growing business, incoming orders rise, more and different machines are added, various resources have to be handled and production lines tend to be more complex. All of this happening in an ever-changing and volatile environment as usual for job shops.

At the point where you are more involved with updating your schedule than actually benefiting from it, you should think about a change.

The more successful you are with your shop, the more complex becomes your decision-making. The more complex your decision-making, the more important it gets to have the following information at your fingertips:

If your scheduling tool does not provide you with that information instantly, you should think about a change.

How quickly can you provide a reliable delivery time if your top customer surprisingly calls and asks if you can squeeze in a rush order?

How quickly can you understand the impact of unplanned machine downtime on your schedule?

How quickly can you reschedule if your subcontractor informs you about a later shipment of the required material?

If your schedule is too static to provide you with answers instantaneously, the likelihood is high that you answer short-term incidents with gut-feel decisions. The result is a schedule that is no longer in-line with reality, of which the result is fire-fighting.

If this sounds familiar, you should think about a change.

Summing this up, here is your checklist with signs that you need a proper job shop scheduling: Does your schedule consume more time than it generates benefits? Does your planning tool give you all information needed at one glance? Is your scheduling tool too static to deal with short-term incidents?

A checklist for you

Summing this up, here is your checklist with signs that you need a proper job shop scheduling:

Getting started with job shop scheduling isn’t trivial. You might be overwhelmed by the options you have, and the limited “spare” time you have to understand these options. This is what we call the vicious circle of getting production scheduling started.

Getting started with job shop scheduling isn’t trivial. You might be overwhelmed by the options you have, and the limited “spare” time you have to understand these options. This is what we call the vicious circle of getting production scheduling started.

We’ve identified five steps to kick-start job shop scheduling and the link brings you to an extensive blog post about those. Here is the condensed version:

To say it with Bill Copeland:

“The trouble with not having a goal is that you can spend your life running up and down the field and never score.”

It makes no sense to start investing into visual job shop scheduling (or any other solution) without knowing what you want to achieve. Take these concrete actions to define your scheduling goals.

I suggest that you first brainstorm general areas of improvement that you want to achieve with implementing production scheduling.

The trick is: write down a (long) list of ideas and them in 1st person. They should be your goals. Nobody will do it for you. Your goals, your investment, your gain.

You won’t be able to achieve everything at once. Prioritize, and make sure you focus.

The trick is: make a ranking list, no priority classed.. This avoids that you add seventeen ideas into the priority 1 class, and then the remaining three into the priority 2 class.

Now, make your (most likely: vague) goals very clear. Make them smart:

Knowing your goals is not enough. You need to translate your goals into requirements for a scheduling system. Typically, one goal translates into multiple requirements.

Here is an example:

My strongest recommendation is that you resist the temptation to try scheduling software on your own. There are solutions out there that pretend that they are super easy. They give you a free trial, or even a free account (with limited functionality). However, job shop scheduling is not trivial (hence this long ultimate guide to it). Do not waste your time playing around with “scheduling tools”.

It is a sign of strength to ask for help.

This also enables you to challenge vendors, and to make sure that they not just have fancy websites, but that they are capable of delivering what they promise. Here is the quick link to get us into a meeting with you.

Let us know what your goals and your requirements are. Then you can decide if there is a fit. This is a faster path to success.

Task 1: List your resources

Resources constitute the capacity that fulfills the operations of your production process. This includes all machines, working stations, or workers available. List them all.

Task 2: Group your resources

If there are similar resources, group them. “Similar resources” typically are those resources that can do similar tasks. This gives your list of resources a better structure. This structure might look as follows:

Task 3: Add your standard resource calendar

You typically have a standard calendar or different standard calendars. Let’s say parts of your shop work one shift Monday to Friday, others two shifts each day of the week. This is what is meant here with a standard resource calendar.

Task 1: Define a job by its metadata

Defining a job by its metadata sounds complicated, but it isn’t. Here is what you should do.

That is all that is needed for scheduling!

Task 2: Define a job by its tasks

Now for every job write down the tasks that you need to do to get this job down. Also, write them down in the sequence of order that you need to do them.

For every task, you need to have the following information:

That’s all. It will be some work.

However, having the data structured properly truly makes it easier for you to get started with job shop scheduling. And by the way: we have an Excel template that helps you with this data preparation work. Download the Excel scheduling template here.

As said earlier: job shop scheduling isn’t easy.

If you consider using a software solution to help you master this challenge, software alone will not do the job. Any software that is promoted to you as “easy and no support needed” is a toy that might be good looking, but most likely is not problem-solving.

If you want to succeed with job shop scheduling, look for software and best practices. Look for software and experts that help you succeed with the software (and achieve the scheduling goals that you developed that nicely).

We condensed our expertise, our best practices, and our scheduling insights into our on-boarding services. It is a service that we deliver to every client. This service is individual, on the spot, tailored to your goals, and affordable.

Make use of it.

Your 5 steps to kickstart job shop scheduling

- a summary

Step 1: Define your scheduling goals

Step 2: Derive major scheduling requirements from your smart goals

Step 3: Talk to scheduling software vendors

Step 4: Gather and structure your data (that is relevant for scheduling)

Step 5: Make use of an on-boarding service

Now that you are ready to start, you need to build your scheduling team. Yes: you are reading this correctly.

Now that you are ready to start, you need to build your scheduling team. Yes: you are reading this correctly.

Although you might be the production planner in your company (or you are the owner and hired a production planner to make this happen), scheduling is no one-man show. Scheduling is teamwork.

Ideally, your scheduling team consists of three roles. We identified them as absolutely crucial to effectively run a scheduling tool. This can be read in more details from a blog post that differentiates scheduling success factors for introducing and for using scheduling software.

Scheduling is no magic pill. It is both: an initial investment and an ongoing investment

Hence, you – for sure – need the backing of your executive management. Ideally, one of your executives is directly involved in the revolving scheduling process. Our experience from working with hundreds of job shops tells us that this the most overlooked success factor.

If this is not possible, an executive member still needs to be in the scheduling core team and receive regular analytics and KPIs on the impact that the new scheduling tool has on the shop.

Well, this sounds trivial. However, we have seen cases in which scheduling was given as a task to an admin worker or even an intern. This does not work.

Your scheduling teams requires a person who is in charge of scheduling. This person must be granted a relevant amount of her time for scheduling.

It is important that the (chief) scheduler gets formally appointed from the executive team, and acts as the first contact for the management for all scheduling questions. This person needs to have a good standing within the organization and a sufficient budget to successfully operate his scheduling tasks.

A schedule is worth nothing if it does not get executed. A production schedule gets executed on the shop-floor and the person responsible for this are the machine operators or the foreman.

When you run a schedule, it is not just important to schedule new jobs. The schedule also must reflect what is happening on the shop-floor, and it must quickly adapt to any short-term incidents that take place.

However, to achieve this, a good scheduling tool must be fed with shop-floor data. It shouldn’t be the task of the (chief) scheduler to always hunt for this data. However, a (chief) operator should be appointed to be held responsible for regularly providing current data from the shop-floor to the scheduler.

There are two things to keep in mind:

To achieve proper scheduling, you need to run a process of

You will need to run this process daily.

Job shop scheduling software can help you with this process, but it will not take away the overall work. To some degree, you can compare scheduling software with a dishwasher:

A dishwasher helps you to achieve your target (cleaning the dishes) in a much more productive way than the manual option (I heard couples stating that they – for sure – would be divorced if they would not have a dishwasher). However, you can only benefit from these productivity (and “life improvement”) gains if you establish a routine to operate the machine.

There must be someone responsible to gather the dirty dishes. Another one is responsible to fill the machine. Then there must be one to select the program and to start it. Finally, the clean dishes need to be put back into the cupboard where they belong. Then the same procedure starts again and again.

Now, that you have your scheduling team in pace, you likewise need to determine

Here are checklists and examples of how this could look like:

If you do not establish routines and/or if you lack the discipline to execute these routines, any job shop scheduling software will be like an unused dishwasher: A waste of money, and a wasted chance to capitalize on some stunning productivity gains.

If you made it to this chapter, you are most likely convinced of the advantages of visual job shop scheduling. Certainly, to implement visual scheduling, a proper job shop scheduling software is necessary. If you are thinking about using such software for your job shop, keep reading.

Here are six requirements for a proper job shop scheduling software.

Time is money. A proper job shop scheduling software should not require days or weeks to be set up: cloud computing solutions guarantee an easy set-up and reduce the implementation effort to a minimum (please note that it still should require a certain amount of training and enablement … as job shop scheduling is not an easy task).

Additionally, cloud-based software is updated automatically and is therefore always up-to-date. If you like to take a deeper dive into this topic, please read 6 reasons for running job shop scheduling software in the cloud.

2. Interoperability

2. InteroperabilityA new scheduling software should be able to integrate your current data and connect to other software programs that are currently used in a job shop. Only then, maximum productivity throughout the whole business is ensured.

State-of-the-art cloud-based production scheduling solutions come with a production scheduling API to easily achieve this kind of interoperability.

This allows you to establish a seamless flow of information from your ERP or business management system to your scheduling software, to your shop-floor, to your analytics and BI tools … and back.

The software should be able to incorporate all the necessary information about the job and the task details, resource capacities, and key constraints.

However, due to the “chaotic” nature of a high-mix, low-volume job shop it should not be based on a too sophisticated mathematical optimization algorithm. Such an algorithm would require too much time for getting set up and for getting trained – without the underlying assumptions being stable.

The software should create a schedule that is represented visually.

Again, a Gantt chart system offers a comprehensive and intuitive illustration of the schedule. The scheduler must gain an overview of the schedule at one glance and must spot conflicts, such as bottlenecks or late orders, instantly. Different views (i.e. job view, resource view, etc.) ensure a deep understanding of the job shop data.

5. Intuitive handling

5. Intuitive handlingThe focal point of the schedule should be the user.

Easy-to-understand handling ensures that the scheduler can make changes, such as changing the priority of a job or adding a resource, with minimal effort.

Again, using the software should save time, hence increase efficiency, instead of bothering with unnecessary sophistication.

Ideally, the software can combine planning data with current shop-floor data. Due to the highly volatile environment of a job shop, the schedule will never be executed correctly.

By updating the schedule with real-time data, e.g. if and when a job has been started or has been finished, the schedule can be moved closer to reality.

If you are a job shop and want to schedule with software, here is what we recommend you to look for:

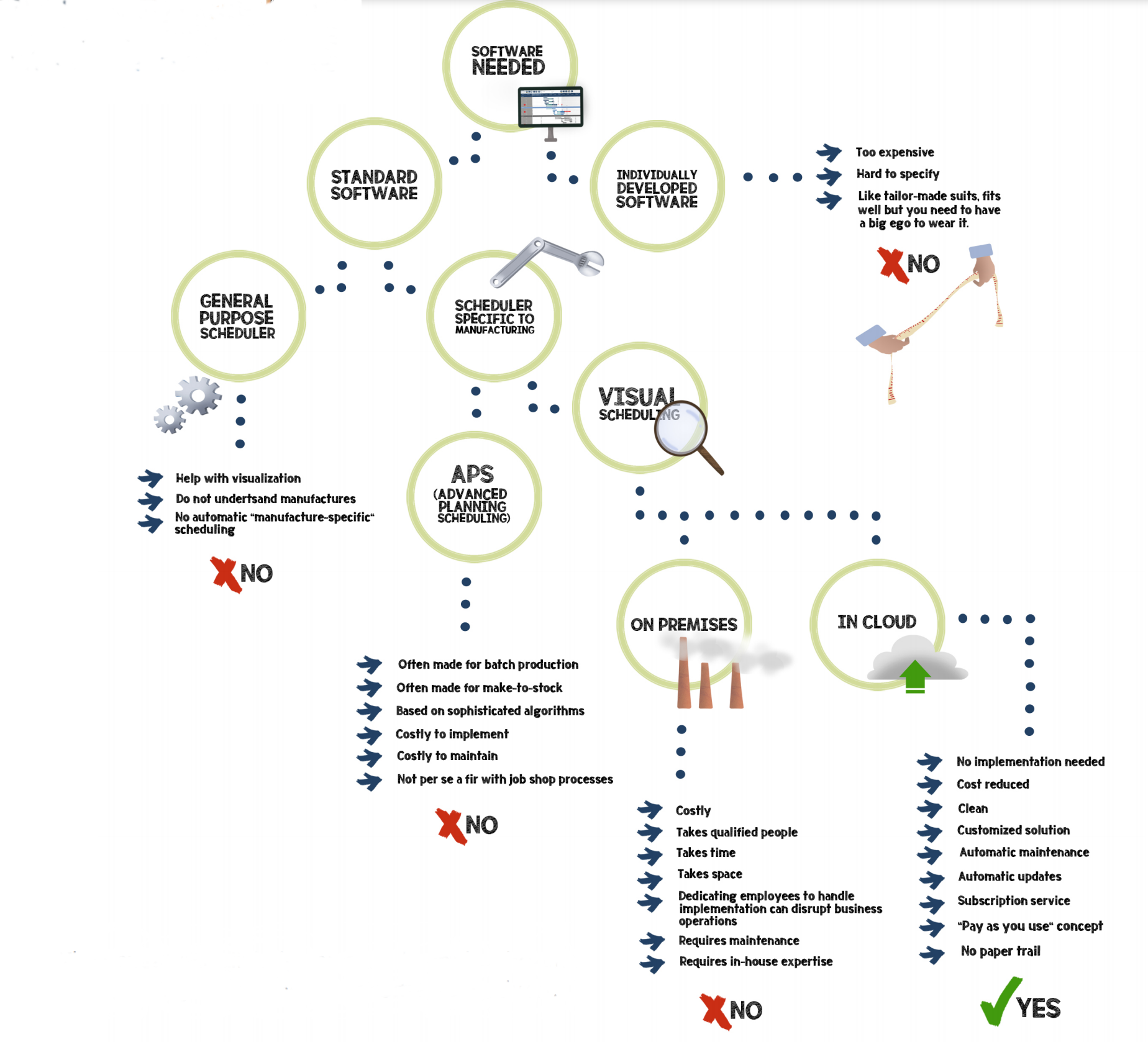

Of course, there are alternatives available to each of these four recommendations. The decision tree shows you why they might not be the best fit for you.

Once you applied these four criteria, you should have a concrete shortlist of proper job shop scheduling software solutions.

We finally recommend that you engage with a vendor who not just ships software, but also provides tips & tricks, best practices, references, and a wealth of job shop scheduling experience.

Here is what you need to remember.

Job shop scheduling can gain you a competitive edge.

Move away from outdated tools such as spreadsheets, whiteboards, as well also dump scheduling modules that are part of your ERP system, or good looking Gantt charts that are not made for job shops (neither for manufacturing).

Move away from outdated thinking and mindsets. Scheduling is not a magic pill, but an ongoing process that requires discipline and routines.

Move away from outdated technology. Windows-based, locally installed applications have served us well – in the past century. Modern applications run in the cloud, are always current, and can get accessed from everywhere, anytime.

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service