Menu

In my blog posts about 'what is job shop scheduling' and why it is important, I made the point that having a proper job shop scheduling tool in place is essential. Let’s add a subtle, but extremely valuable, element to that: Visual job shop scheduling. As mentioned already, one benefit of job shop scheduling is gaining transparency and visibility over a production. Including a focus on visuals, this aspect is taken to another level.

They say a picture is worth a thousand words. This is why we use signs to convey road traffic policies, graphs to visualize data or logos to represent a brand identity. Communicating by using gestures, signs or images is the most effective approach of sharing knowledge as the human brain processes information through images.

In fact, around 50 percent of our brain is busy with visual processing.

The conclusion is evident; visuals are a powerful tool in any kind of communication and outperform words and texts anytime. This insight has to be included in the discussion of job shop scheduling.

An by the way: this blog post just deals with the job shop scheduling basics. If you want to learn more about the entire job shop scheduling problem, please have a look at our ultimate guide to visual job shop scheduling.

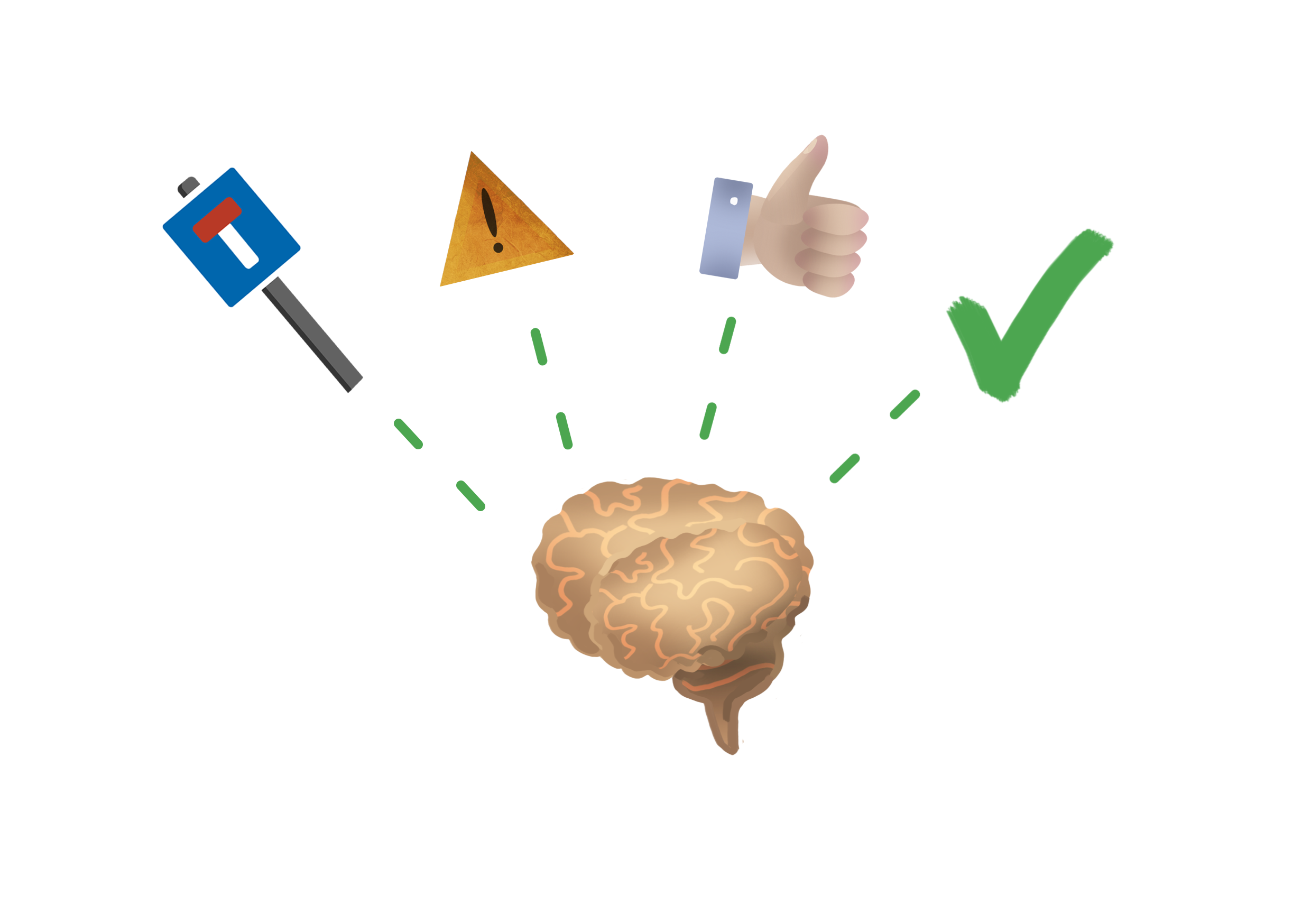

At this point, you might wonder what visual job shop scheduling actually looks like. Broadly, it is a software specifically aiming to assist small HMLV (high mix, low volume) manufacturers with their production process. Usually, a job shop has to deal with ever-changing dependencies, deadlines, resource capacities, incoming orders and connections to supply-chain partners.

A visual job shop schedule provides the manufacturer with a clear picture of what is going on at the moment by visualizing all the relevant data. Thus, it is not an advanced production scheduling (APS) software which aims to optimize make-to-stock production lines by achieving maximum efficiency and exploiting economies of scale and scope.

On the contrary, the main focus lies on creating visibility. Here are some key components of visual job shop scheduling:

1. Simplicity

1. SimplicityA proper visual job shop schedule is easy to understand and easy to set up. There is no need to become an expert as there is no complexity associated with the usage of the software. New updated data can easily be included in the schedule. New jobs or resources can rapidly be added and represented visually.

2. Understanding

2. UnderstandingThe goal of a visual job shop schedule is to provide the manufacturer with an understanding of the entire job shop floor. With one glance, one should be able to see the current status of all jobs, resource utilization levels, delays and machine capacities. While usually chaos and a constant firefighting mode dominates job shops, a visual schedule aims to represent all the relevant information associated with successfully managing the production.

3. Scenario planning

3. Scenario planningInstead of creating an entirely new plan for different options a manufacturer can undertake, a visual job shop schedule can instantly show the precise effect of particular choices; Adding a new job, changing the working times of a machine, adding new resource capacities or changing the priority of certain orders. This creates a tremendous advantage. Job shop manufacturers can base their decisions on knowledge rather than on intuition while further reducing the time needed for decision making; hence, options can be evaluated at one glance.

By having all the important information visually present at one glance, a manufacturer can easily spot bottlenecks and constraints. These can be obvious problems such as a delay indicated by a specific sign or constraining waiting times in front of a machine with limited working times. As bottlenecks can be identified at an early stage, further negative effects can be avoided by instantly taking corrective actions. The ease of finding such factors leads the path to continuous improvement; an assumption that there is always room to enhance a production on a regular basis.

By having all the important information visually present at one glance, a manufacturer can easily spot bottlenecks and constraints. These can be obvious problems such as a delay indicated by a specific sign or constraining waiting times in front of a machine with limited working times. As bottlenecks can be identified at an early stage, further negative effects can be avoided by instantly taking corrective actions. The ease of finding such factors leads the path to continuous improvement; an assumption that there is always room to enhance a production on a regular basis.

Once the visual schedule creates a bigger picture of the entire production, a manufacturer can realistically assess delivery dates and throughput times. These insights can be used to have a clearer view on future production as well as future performance.

In order to further enhance the quality of insights from the user’s point of view, on can switch between calendar view, job view and resource view. Thereby, it becomes even easier to spot certain components and inter-dependencies in the schedule.

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Job Shop Scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think