Menu

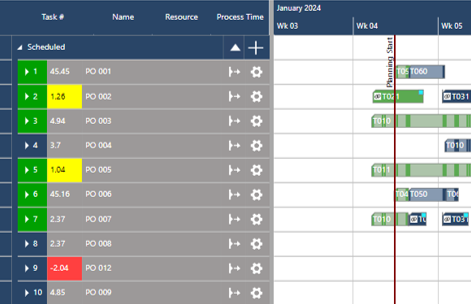

Managing production schedules in job shops can be a complex and daunting task, yet it often begins with a simple step. New orders are typically added to the existing list of jobs, and it is the responsibility of the master scheduler to assign a priority or sequence number to each new job. This priority can be determined based on various criteria, such as the due date, job duration, or other relevant factors.

The use of priorities in a high-mix low-volume production environment is essential. Therefore, most Automatic Finite Scheduling engines, tailored to meet the requirements of job shop planners, managers, or owners, provide a priority-based scheduling approach.

Tip: Automatic Finite Scheduling (AFS) is the key to success for job shops

This means that jobs are assigned to priority categories that then serve as criteria for the scheduling engine. In the most extreme case, every job even gets its own category or individual priority. The question in regular AFS usage is then how to prioritize the jobs best.

In the following, let's assume that the AFS provides the option to define as many categories as needed. In any case, from my point of view, there should be at least five classes (from very important to least important).

What I have seen is that the majority of AFS users start with taking the due date to derive a priority: the closer the due, the more important the job. This is a valid approach. But from my point of view, there are more goal-oriented criteria to consider, as explained in the following.

Of course, this list can be continued almost indefinitely. Circumstances such as the strategic customer relationship and direct financial aspects certainly also play a role in assessing the importance of an order. With all this complexity, I have concluded that the best thing for the scheduler is to be able to evaluate each job individually and, if necessary, according to differently weighted standards. What is important to me, however, is that the methodology always leaves room to be able to squeeze in particularly important orders at short notice. This can be achieved by reserving the highest priority class only for the so-called "boss jobs." If such a job has to be added to the existing schedule, the scheduling engine does this automatically using the appropriate priority.

Overcoming bottlenecks: the key to successful job shop scheduling

Effective scheduling in an HMLV production environment-the jpi concept

User roles, hierarchies, and responsibilities in job shop scheduling

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Job Shop Scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think