Menu

Unlike large process and discrete manufacturing, SMB job shop operations often rely on a labor-intensive scheduling process. However, because of dynamic arrival patterns, frequent order changes, and random sequencing on almost every small batch, finding effective ways to optimize your resources and reduce “makespan” times typically takes a back seat to the pressing urgency of simply arranging your daily production tasks.

Since many of your customers already utilize lean strategies to organize their own inventory and production runs, experiencing sporadic or unreliable order completion negatively effects your reputation as a vendor, and your revenues. From this blog you can learn 10 best practices with respect to machine shop scheduling that help you master these challenges.

By recognizing the factors that will make your scheduling process easier, you can incorporate machine shop scheduling best practices that improve your ability to deliver quality parts and components on time, while simultaneously improving your floor efficiency metrics.

The biggest challenge faced by SMB job shops is volatility. Therefore, machine shop scheduling best practices focus on developing an actionable strategy that addresses two core certainties: delivering accurate information regarding what needs done, and when; and the ability to easily view the impact and implications of specific job tasks.

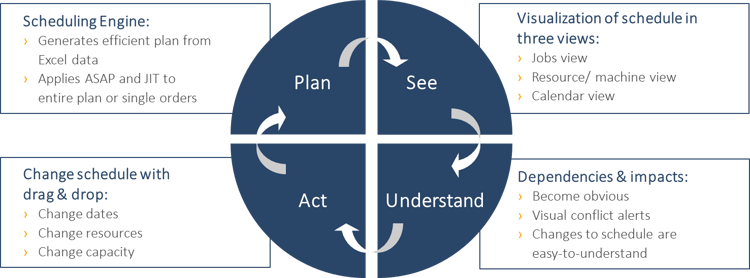

These top 10 machine shop scheduling best practices center on developing an active planning process, unobstructed visualization, clear understanding, and ways to take immediate action. The machine job best practices also can be seen as best practices for job shops as you can see from our ultimate guide to visual job shop scheduling.

Your production planning/scheduling tool needs to work together with your other resource management systems to ensure maximum productivity. A smooth integration of production load information, along with labor and machine capabilities allows your scheduling tool to expand together with your total software landscape.

Your production planning/scheduling tool needs to work together with your other resource management systems to ensure maximum productivity. A smooth integration of production load information, along with labor and machine capabilities allows your scheduling tool to expand together with your total software landscape.

Schedulers must arrange jobs according to finite capabilities, so your scheduling engine needs to automatically integrate the most important aspects of the job in relation to capacity. Moreover, necessary constraints like warm-up and wait times for machines must be accounted for, along with variables priorities, earliest due date, etc. A dedicated scheduling engine provides for these type of limits and dependencies automatically.

You schedulers need actionable information concerning the inclusion of rush orders or changes to existing jobs. A detailed “what if” scenario provides quick, accurate implications so that the schedule can be adjusted for optimum productivity.

Your scheduling tool needs to provide, clear, visual language that is easy to understand, and that highlights any potential conflicts. Speaking colors (like red warnings) and recognizable symbols must be included to instantly show bottlenecks and convey the impact new order additions make to the current production plan.

Your job shop deals with more variables than can be addressed by a one dimensional, visual system alone. A truly comprehensive view incorporates both your resource parameters (capacity) and your job details, with all their explicit and implicit dependencies.

Instead of viewing data in simple rows, columns, and cells, you should have 3-dimensional access to:

Machine shop scheduling best practices must deliver proactive scheduling support, which means that alterations must trigger scheduling conflicts immediately. The visual system allows your schedulers to instantly see where any conflicts will occur with resources, so that they can better understand subtle implications to the schedule.

Successors and predecessors must be automatically altered when an operation is changed, in order to allow for easy interpretation the fluctuations you face each day, making order impacts and dependencies obvious. This type of superior presentation provides actionable intelligence for your schedulers.

The ability to alter your schedule to meet changing demands provides you with the tools and intelligence to ensure that you’re optimizing your operations. Change your machine allocation, dates, and times using a drag and drop technique that continues to adjust the schedule as you work.

Your schedulers also need to be able to quickly alter your capacities, such as inserting extra shifts and additional labor, or accounting for absent personnel.

You also need to be able to switch back and forth between production strategies (like ASAP and JIT) to ensure that delivery dates are met. This best practice offers flexibility that allows you to optimize your floor operations.

Machine shop scheduling best practices deliver the ability to alter your schedule to meet changing demands, and provide you with the tools and intelligence to improve your most important business metric: ensuring timely deliveries to your customers. If wou want to summarize this in four words, you can state that a proper machine shop schedule should enable people to easily plan their production orders and resources, see the schedule at one glance, quickly understand dependencies and impacts, and have the capability to rapidly act in case of any issues.

Want to learn more best practices for scheduling your machine shop? Please feel free to download our complementary Ebook "A comprehensive introduction into machine shop scheduling":

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Machine shop scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

Comments (10)