Menu

Trying to orchestrate well-organized, effectual production in a machine shop, using a manual scheduling system is extremely challenging. Although advanced algorithms and lean practices are very effective for improving productivity metrics in discrete operations, in a machine shop, the number of variables you face creates a volatile scheduling environment. This blog post discusses five requiremnts for an effective machine shop scheduling software which can cope with this volatility.

Your own inventories, processing times, and logical dependencies, combined with frequent order alterations, fluctuating resource constraints, and customer “rush” requests generate a situation fraught with unpredictability. And, the typical result of gargantuan white boards and Excel sheets is a lot of frenzied activity, frustration, and late deliveries.

To effectively control floor productivity in a machine shop environment, many businesses adopt some type of scheduling software. The idea being, that additional technology will somehow produce the best practices that will drive production results. However, often the “solution” generates even more confusion by omitting critical information, or because of a lack of interoperability.

In today’s “time-based” competitive market, you simply can’t afford the revenue losses that accompany late shipments. Since your customers are depending timely deliveries, your machine shop scheduling software must facilitate the orderly execution of your shop floor activity, support user communication, and ensure the achievement of production best practices. As such, a proper scheduling system becomes the clockwork of your shop floor operations.

In today’s “time-based” competitive market, you simply can’t afford the revenue losses that accompany late shipments. Since your customers are depending timely deliveries, your machine shop scheduling software must facilitate the orderly execution of your shop floor activity, support user communication, and ensure the achievement of production best practices. As such, a proper scheduling system becomes the clockwork of your shop floor operations.

The following five requirements outline the software factors necessary for introducing the planning, visualization, comprehension, and agility you need to achieve “five nines” (99.999%) delivery metrics.

Click to tweet the below:

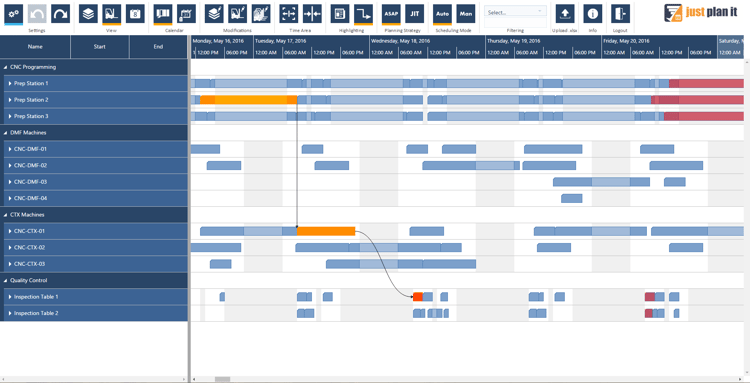

Machine shop scheduling software must offer clear, easy to understand planning parameters in a quick to learn format. Your schedulers shouldn’t need extensive training to operate it. The best option is a highly visible Gantt chart system that features an intuitive, yet comprehensive approach, allowing for quick action and enhancing operational agility.

Visual planning allows you to view all of your resource capacities (machinery and employees) and job details, giving immediate warnings when and where any conflicts or wastes (idle gaps) occur. Moreover, by allowing the user to build plans based on common strategies like JIT and ASAP, and the ability to selectively prioritize jobs, you facilitate timely order completion.

The user should be the focal point from which all scheduling data is targeted. By providing your scheduler with simplified planning parameters and job insertion (minimal clicks, “drag and drop” functions), your machine shop scheduling software will institute best practices that will streamline:

Your machine shop scheduling software must flawlessly integrate all of the finite capabilities of your shop. The total number of jobs must be coordinated according to volatile, moving constraints, and the software must provide a visual aspect of the logical dependencies of operations, comprehensively. This means that the individual predecessor-successor-relations of your jobs are considered automatically, everytime you work on your schedule.

This inevitable Integration of existing dependencies minimizes the planning efforts in comparison to hand made solutions like Microsoft Excel and improves your operational agility tremendously.

Because your scheduling process essentially consists of repeated re-scheduling, your scheduling software should offer automatic tools that instantly deliver actionable information. For example, to ensure operation efficiency in the face of rush order and alteration requests, your schedulers need to know exactly what impact the changes will create.

Likewise, in the event of an unexpected break-down, you need to be able to allocate another machine to fill the gap, without influencing other processes. Look for the ability to create “what if’ scenarios.

By providing a clear delineation of all successors and predecessors, relative dependencies, and other influences, along with the power to manually alter the current schedule, you gain an interactive system that eliminates backlogs and inaccuracies.

Scheduling software for your machine shop must be able to function with your current enterprise resource planning system (ERP) and other business software applications to ensure maximum productivity throughout your business.

Naturally, your scheduling software should easily integrate your inventory data, but interoperability with other systems like CRM and vendor management programs create an effective way to monitor mission critical metrics and identify possible liabilities. For example, the ability to connect with management software, helps track vendor quality and delivery performances, and smoothly transfers all of your Excel information.

This ability allows your scheduling software to evolve and grow sustainably together with your total software landscape.

This requirement is really a must have in today’s business environment. Out-of-the-box software that functions with cloud technology removes the implementation hassle. You should not have to spend days (or even weeks) operating at a minimum capacity to initiate the program. In fact, cloud computing solutions offer enhanced security and uptime.

No need to worry about costly upgrades, increasing your infrastructure and hardware, or adding additional IT personnel. Cloud based delivery eliminates the hassle of adopting state-of-the-art scheduling software for your machine shop.

The right tool will engender necessary best practices, while increasing floor communication and productivity.

Want to learn more about how to best manage your machine shop schedule? Then download and read our complementary Ebook:

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Machine shop scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think