Menu

Microsoft Excel is certainly one of the most used standard software products of today - if not the most used. The plethora of both user types and application areas is very remarkable: Companies of any size use the application in almost any functional area. Just as striking: The application, designed as spreadsheet program, is very often used for rather untypical purposes. Everybody knows this “Excel Monster Application”, which is designed to deliver an output which the respective company pretty much depends on, but which basically no longer can be handled appropriately. This phenomenon particularly can get observed when it comes to the operational production scheduling within small to mid-size manufacturing companies. Hence, this blog post discusses the possibilities and limitations of an operational production scheduling with Excel.

During their early years, the small and mid-size companies mentioned above typically don’t use a dedicated or even integrated software landscape for their business planning processes. For obvious reasons: especially in these early years both quantity and complexity of planning data are manageable and a “homegrown handmade” Excel solution perfecly does the job. Machines are allocated to orders “manually” and a rough operational production schedule with delivery dates per order is created. A new order will be “puzzled” in as good as the Excel sheet allows. In this scenario, Excel proves to cope with the requirements of an operation production scheduling.

But, however, even the “manual” integration of jobs that in the long run cannot be reasonably supported through Excel, reaches its limits first, when the number of orders starts to grow. It gets even worse if jobs consist of several operations being logically dependent. And - if the business grows - usually more machines will be purchased adding to the planning complexity. In addition, due to the growing business, the small and mid-size manufacturers will have to vary their order types, so that increasingly different order types with various routings will have to be scheduled. In general, the situation in most cases can be described as follows:

But, however, even the “manual” integration of jobs that in the long run cannot be reasonably supported through Excel, reaches its limits first, when the number of orders starts to grow. It gets even worse if jobs consist of several operations being logically dependent. And - if the business grows - usually more machines will be purchased adding to the planning complexity. In addition, due to the growing business, the small and mid-size manufacturers will have to vary their order types, so that increasingly different order types with various routings will have to be scheduled. In general, the situation in most cases can be described as follows:

So, you could say: "my plan constantly is in motion!”, and exactly this motion is not supported by Excel solutions.

If an order consists of several logically dependent operations – no matter whether in predecessor-successor or predecessor-predecessor relations – all successors and predecessors have to be shifted manually when an operation is moved backwards or forwards. There’s no planning logic whatsoever between an order’s operations, this often resulting in manually moving around the planning data quite frantically.

The situation gets worse by the fact that one order in the production schedule cannot be viewed as if it would the only one. Of course, all orders compete for the same scarce resource capacity. This means that if one operation and all the logically related operations of the same job have been moved, it has to be verified whether the new temporal position of the operations is permitted at all or whether there will be resource conflicts with other operations of other orders. This permissibility check is also not supported by Excel in a purposeful way.

The situation gets worse by the fact that one order in the production schedule cannot be viewed as if it would the only one. Of course, all orders compete for the same scarce resource capacity. This means that if one operation and all the logically related operations of the same job have been moved, it has to be verified whether the new temporal position of the operations is permitted at all or whether there will be resource conflicts with other operations of other orders. This permissibility check is also not supported by Excel in a purposeful way.

This in fact lets the planner painfully suffer if an especially important order – let's call it "rush job" – has to be added to the plan on short notice. There are simply no tools to modify the plan in an easy way so that the priorities inherent in this situation will be taken into account. And now, at the latest, Excel changes from being a useful device to becoming a troublesome task, the maintenance of which using up important and scarce capacities without providing the benefit once intended.

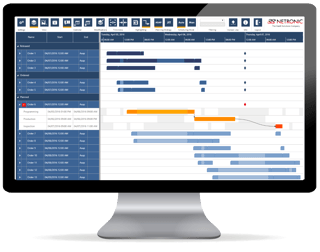

At this point, it is more than obvious that only an adequate software tool will provide the desired support for the altered planning situation. Mastering the above mentioned “plan in motion” is the challenge and at the same time the necessary basis for successful planning. So, as a consequence, the software tool should provide the following features to meet the requirements of operational time and resource scheduling:

Integration of planning logic for a simple visualization of logical dependencies of operations

Integration of planning logic for a simple visualization of logical dependencies of operationsDoes the outlined planning dilemma, sound familiar to you? Has your operational production planning with Excel reached its limits? Then test just plan it! We’d be glad to create a demo version for you on the basis of your data. You will see and grasp immediately how simply just plan it will bring your operational production planning to the next level you need so urgently.

Let's start with a demo, and then we are happy to provide you with a trial account.

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Excel-based production scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

Comments (1)