Menu

First of all: I bluntly admit that Excel is one of my favorite software tools, and that Excel truly has supported me - in various functions - throughout my career. We still base some of our own companies' reports on Excel. Excel is a kind of swiss army knife within the Microsoft Office product family, and there are a zillion reasons and use cases why Excel is just cool. Besides the ease-of-use and the sheer unprecedented flexibility of Excel, to many folks it feels as "free" software as it comes within their Office package anyway. Hence, it is no surprise that most SMB make-to-order manufacturers and job shops typically start building their initial production schedules with Microsoft Excel. In the beginning, this tends to work rather well. But over time, the production schedule with Excel stops to cope with the pace of the business. This blog post reveals four signs warning you that your Excel-based production scheduling is about to harm your business.

Let's recap: an Excel spreadsheet built for production scheduling is supposed to be a tool helping you to better plan and monitor your manufacturing processes. That means as tool it's function is helping you to achieve a higher accuracy in delivery time commitments and to better utilize your resources. If your Excel-based production schedule sufficiently helps you with exactly this, I suggest you now stop reading this blog post and continue running a stunning job shop.

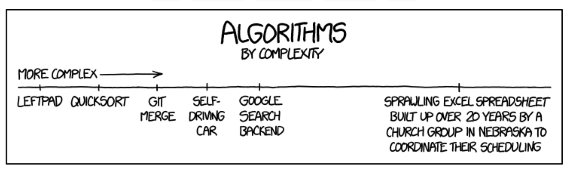

Hey - you did not stop reading. That means you eventually had kind of thoughts like "my revenue is killing me". Means, your business grows ... and with it the workload to manually maintain your Excel sheet. Also, you find yourself permanently adopting and tweaking your spreadsheet so that over time a lot of "tribal knowledge" finds its way into your key production scheduling tool. Slowly but steadily, your initial slick and lean tool has become quite a beast, consuming a lot of your time, energy and brainpower to keep it being alive. This is not how you started and it might be about time moving to a next generation tool - beyond your Excel beast.

Not ready yet to quit planning your production with Excel? Given the energy you put into building and maintaining this tool, I truly understand. However, if you answer one of the below questions with "no", the likelihood is high that you no longer can see the forest for all the trees. Means: you might have all information in your spreadsheet, but it does not help you quickly see what is relevant.

Not ready yet to quit planning your production with Excel? Given the energy you put into building and maintaining this tool, I truly understand. However, if you answer one of the below questions with "no", the likelihood is high that you no longer can see the forest for all the trees. Means: you might have all information in your spreadsheet, but it does not help you quickly see what is relevant.

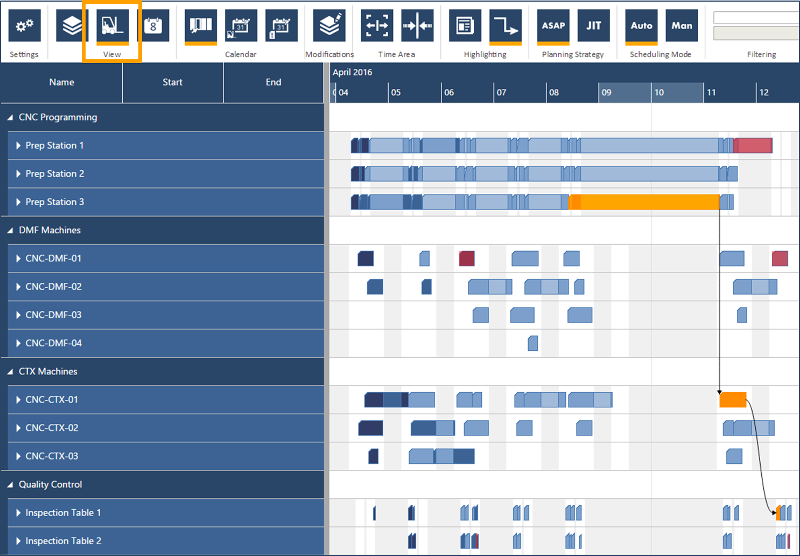

I get it: with Excel you can build powerful stuff, and it even might help you to visualize your production schedule. However, Excel still is a spreadsheet and hence it is a rather static tool. What do you do if you get the above mentioned super urgent order? How many cells in your spreadsheet do you have to manually touch and change? How many dependent cells will you need to update as well? How do you modify your schedule if a machine breaks down? Can you quickly and temporarily "disable" this resource in your schedule and automatically reschedule all affected orders? Or is this the moment of time, when you ignore your Excel-based scheduling tool and just decide based on your gut feeling ... leaving you with the unpleasant task of making your spreadsheet reflecting reality again - after the fact.

I have seen this many times: if the business grows, smaller make-to-order manufacturers and job shops typically are forced to do something to formalize their scheduling and planning - or suffer the pain of processes going out of control.

Fair enough: my Marketing folks reminded me that I am writing for small make-to-order manufacturers and job shops, and not for a church group. Also, I do not particularly care if you are in Nebraska or in any other great place on earth. However, working with small production companies around the globe over the past couple of years made me look at lot of grown Excel spreadsheets that seemed at least as complex as the above cited Google search backend. OK, no more kidding. If you feel you need to hire an Excel guru to keep mastering the complexity of your scheduling spreadsheet, consider changing the approach. Consider changing your production scheduling tool and invest into software (or new machines) rather than in a spreadsheet superstar.

You feel like moving away from your Excel-based production schedule? You are unsure how to start and you are shy of huge investments into software and IT? Here is the deal: you request a demo of just plan it via the below button. If you think, this could be the right move forward, you can send us your Excel schedule and we build your own just plan it trial account from it. This will give you the opportunity to plan, see, understand and act - with your own data. Let's go!

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Excel-based production scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

Comments (1)