Menu

There are many approaches of production scheduling and there are many critical factors overall. But if you want to boil it down then - in my eyes - you end up in the challenge of establishing a routine of a regular scheduling process. What does that imply? Let´s have a closer look to the single components to consider.

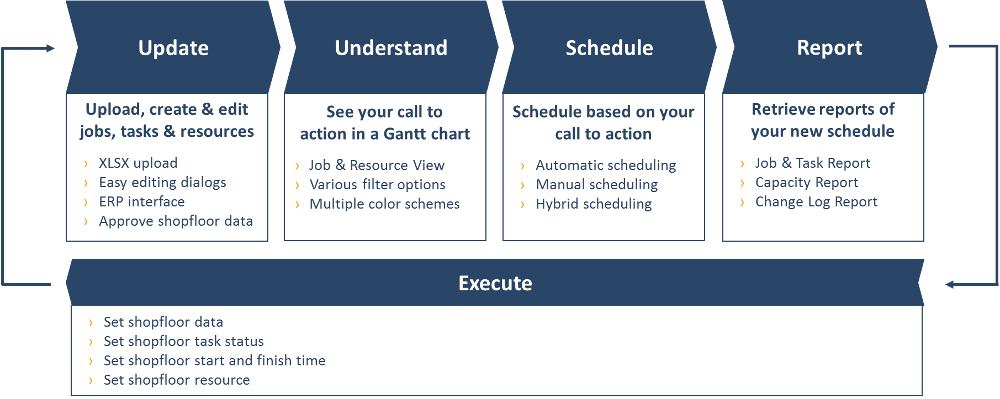

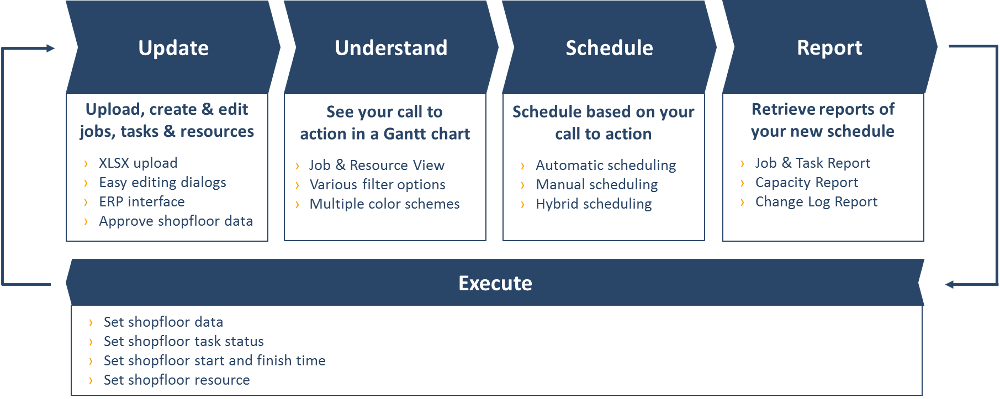

The process is a revolving cycle that includes – at least – following aspects:

It is crucial that the scheduling process gets a very high relevancy within the company. Therefore, it is required that the process has one particular owner that bears the responsibility: „the scheduler“. The scheduler needs to be legitimated and supported by the top management. This includes an adequate budget of time to keep the scheduling process running.

As described the scheduler's main task is to gather information, hence to communicate. Thus the scheduler should be an influential person with a good reputation within the company. As scheduling is affected by many company units and quite certain by the entire production it is compulsory that the scheduler has to succeed to assign the scheduling tasks to every single shopfloor employee. If there is just one lack of information the quality of the whole schedule is affected negatively.

It is the scheduler's ongoing and revolving task to keep the scheduling process running. Therefore, it is helpful to find the right time window of how long one scheduling process shall last. The is mainly related to the volatility of one´s business. In a high mix low volume surrounding it makes sense to have this routine daily based.

Furthermore, it is highly recommended to use an appropriate software that supports you in your scheduling process routine and that backs the scheduler in his information gathering tasks. A software that supports tracking of shopfloor progress data and that allows to easily integrate it into the schedule as well as other information (such as new production orders, changed priorities of existing jobs or machine breakdowns) will bring great benefit – not only by saving a lot of time.

As the software takes over most of the communication tasks, it could be possible to abstain from the compulsory morning production meeting. Even if this might theoretically possible I would not recommend to do so. But imagine all your information gathering and recalculation is done and you could keep this meeting shortest and focus on the special and critical aspects to directly contribute to the quality of your output!

To wrap things up: are you the manager of a make to order manufacturer and you see a lot of potential to enhance the quality of your scheduling? Then deputize and empower a competent „Scheduler“ and fit him up with an appropriate scheduling software, both to establishing a routine of a regular scheduling process.

On the look for proper job shop scheduling software? Download our free ebook to get some guidance, or continue reading our ultimate guide to visual job shop scheduling.

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Scheduling Best Practices

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think