Menu

There seems to be a conflict that challenges the production scheduler of high-mix low-volume manufacturing companies every day: an increasing number of jobs leads to a work center bottleneck, which affects the delivery dates of the scheduled order backlog. Outsourcing of operations -or in some cases even intermediate products- to reduce the workload of the bottleneck can get them out of trouble but then they reduce their profit, right? No, by experience in most HMLV use cases, this is not true! Sometimes outsourcing intermediates does not reduce, but on the contrary, helps you earn more money. Let me show you how to find it out.

In my series of blog posts, I investigate typical production scheduling challenges for job shops and make-to-order manufacturers that keep them up in their usual day-to-day planning. Here comes the third one about when outsourcing can have a positive impact not only on the on-time delivery of jobs but also on the company's profit.

Small companies working in a high-mix low-volume production environment, often face the following challenge when the order situation increases: Do I accept the order with the requested delivery date, overloading some of my work centers, and risking not being able to meet my schedule on some other orders, resulting in late deliveries?

In many cases, the service to operate a specific kind of task, needed to complete the final products of the sales order, can be purchased from external partners. However, this route is rarely taken, because using an external partner means generating additional costs, which ultimately reduces profit. BUT: this way of thinking is often too short! Because increasing the capacity of a bottleneck, will improve the total flow in the production process and hence will improve your throughput. Accordingly, more jobs can be completed in the same amount of time, more sales can be generated, and this ultimately leads to more money being earned - provided that the additional cost of outsourcing does not exceed the additional revenue, of course.

These findings are due to the Theory that Constraints, a process management methodology developed by Eliyahu M. Goldratt, which says in short, the overall goal of a company is earning money. The goal is limited by constraints, like a bottleneck. Throughput is one of three measurements to manage and control the goal. So, it's all about managing the bottleneck to increase the throughput and hence earning money. Read more about "The Theory of Constraints and its application to job shop scheduling" in this blog post.

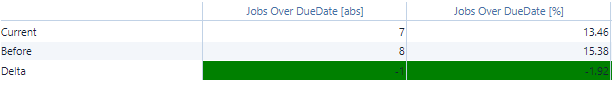

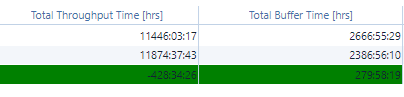

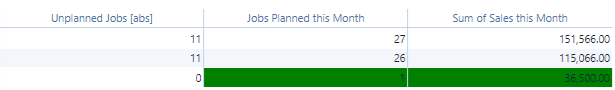

How can I, as a planner or manager, know whether outsourcing will have a positive or negative impact on my profit? Or put it in another way: will the additional costs for outsourcing be compensated by the additional sales of execution of more orders? Our experience says that outsourcing is usually worth it. However, you need a tool that makes the individual parameters transparent and provides visibility for the decision. For this purpose, we have added a function in our production scheduling software just plan it, which shows the before and current effect when you change the production schedule. This also includes the assignment of a task to an external resource. Because just plan it is a web-based visual scheduling tool with an interactive planning board, you drag & drop the operations and immediately see the impact on the four key figures for successful scheduling: delivery failure, throughput/buffer time, planned/unplanned jobs, and sales:

Et voilà: everything is green- this means that your implemented change on the schedule has positively influenced all four key figures - you reduced over due-dates and throughput time and improved numbers of planned jobs and sales. This is a strong indication that the outsourcing plan leads to more profit. A final check by the planner or manager of a job shop, who usually knows the costs for outsourced intermediates, tells them if the plus in sales compensates or even exceeds the additional costs for outsourcing.

Watch this short live sample from my colleague Dave based on which the results shown above have been achieved - and see how outsourcing can have a positive impact on the delivery date as well as on the profit :-)

How to squeeze an urgent job into the production schedule /with video

How to use free capacities in your production schedule to increase revenue /with video

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Machine shop scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think