Menu

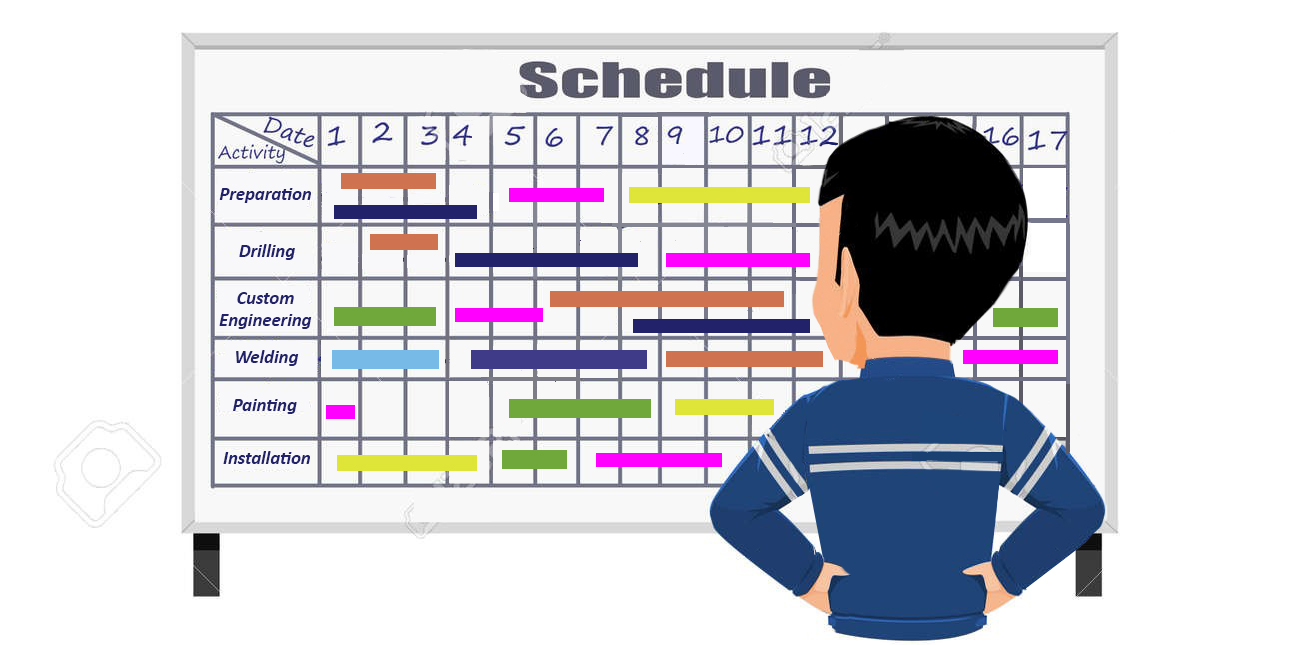

Unused resource capacities are a thorn in the side of every production scheduler because they prevent revenue. However, especially for make-to-order companies or high-mix low-volume manufacturers, it is difficult to uncover free capacities, because of the complexity of the schedule and the lack of overview.

Well, it is difficult, but it is not impossible :-) And when you use the production scheduling software just plan it, it is even very easy. Let me show you how to do it.

Last month I started my series of blog posts with typical scheduling challenges of companies, producing customized products in low batch sizes, like make-to-order companies, job shops, engineering companies, etc. My first blog post was about how to squeeze an urgent job into the production schedule in a high-mix low-volume production environment and the delivery date given by the customer was an important part of the game.

Let's now look at the production schedule from a different perspective: we want to see if any unused resources in the near future could be used for additional jobs that will ultimately bring us additional revenue. The delivery date is not the limiting factor.

These four questions need to be answered first before thinking about possible resource utilization options:

All these questions can be answered by just plan it in just a few steps:

Now you want to see this use case in practice? My colleague Dave, a scheduling expert for make-to-order companies, or high-mix low-volume manufacturers gives you a live demonstration, with a detailed explanation. Enjoy watching this video 😊

Free ebook: A comprehensive introduction to machine shop scheduling

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Machine shop scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think