Menu

Our production scheduling software helps a make-to-order company, a job shop, or a high-mix low-volume manufacturer to faster schedule their jobs, use their resources more efficiently, and to plan more accurately respectively to deliver on time. These companies unite a lot of typical problems that do not exist in serial manufacturers. Hence I decided to start a series of blog posts, that will highlight some typical scheduling challenges and demonstrate how they can be solved quickly and easily with just plan it.

This first blog post is about adding urgent jobs to the production schedule.

Do you know this situation? A customer calls and asks you to manufacture a special product for him, e.g. a customized filter system, at a short notice. Now your challenge is to squeeze this job into your current production schedule without violating the due dates of the existing jobs.

The typical process is that sales first check the department that is going to be the primary area where the work is going to be done. Back to our sample above, the job has CNC requirements, so the milling department is likely the area where most part of the work will be done. The customer asks for a short-term delivery date. Now sales need to check if production is quite busy during this period. So he talks to the production manager, responsible for the production schedule if milling will be able to work on the new, urgent job and deliver it on time.

If milling is very busy, the Tetris game starts. What are the consequences of shifting the already planned jobs? What effect does the postponement of one job have on the others and will they now no longer be completed on time?

These are the "working tools" in just plan it to add a new job to the schedule:

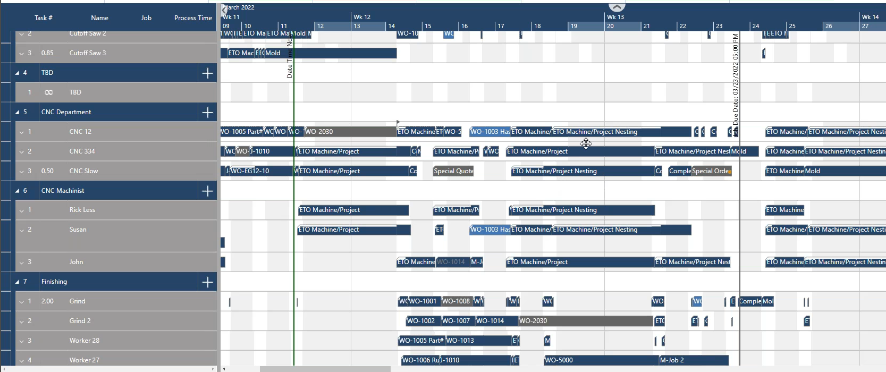

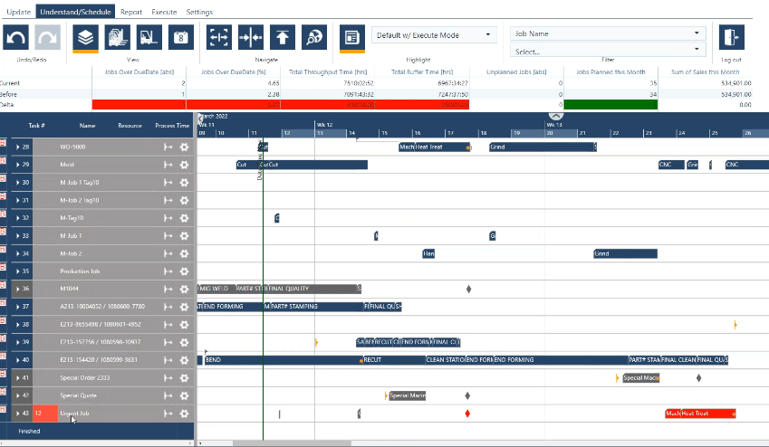

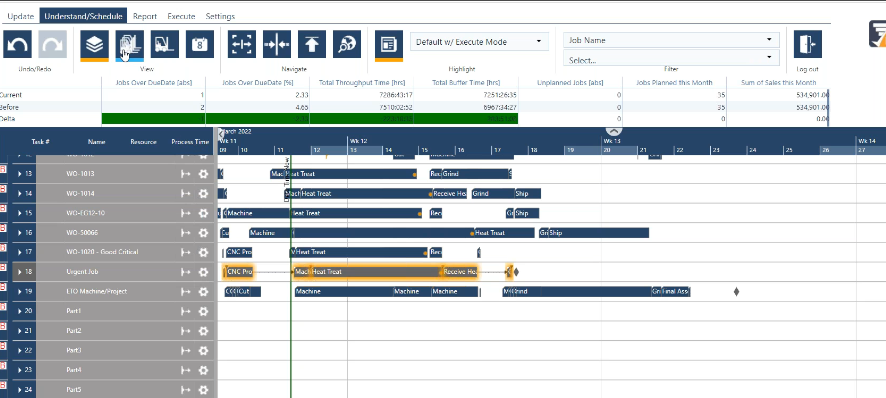

#1 A planning board, with a list of jobs and their sequence number in a table at the right side of the Gantt chart and the jobs along the timeline gives you an overview of all jobs.

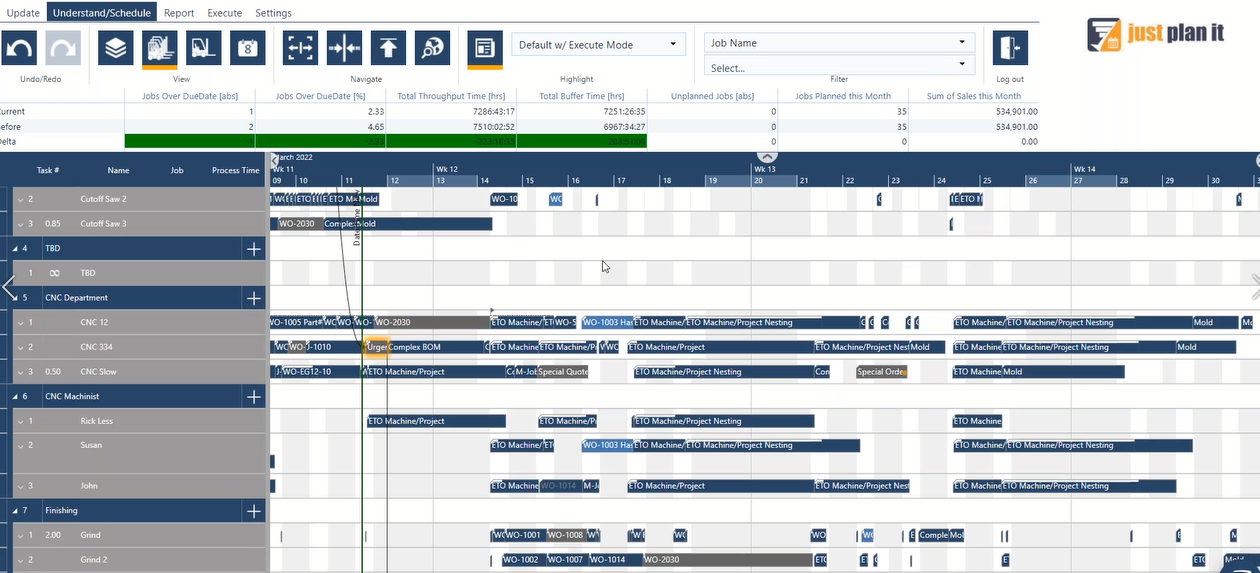

#2 You can switch from the order view to a resource view to see the job tasks and the resource allocations.

#3 In the resource view you hence see how busy the department is, where the work is going to be done.

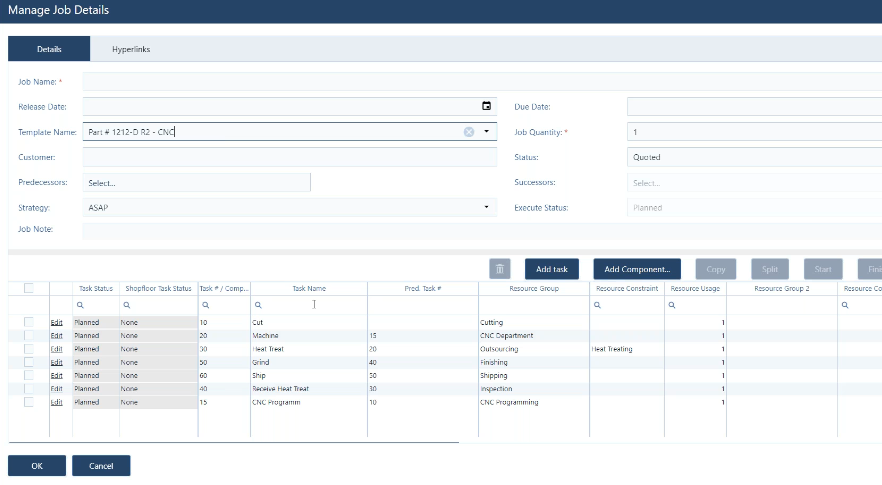

#4 You add the new, urgent job to the list of existing jobs including numbers of parts and due date, by using templates.

Now back to our sample. The customer needs the products on May 17. On the planning board, you see that the CNC machines are busy at this time. Let's see what steps to take to squeeze in the urgent job in your existing production schedule:

You create a new job by using a template, with routings, quantity, due date etc.

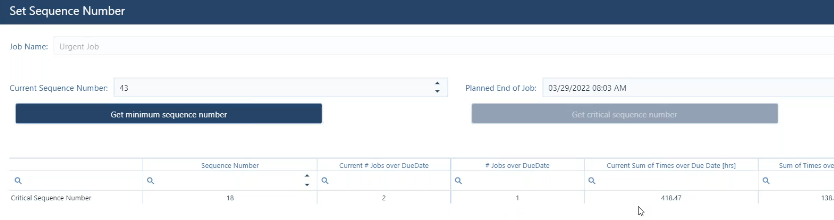

The new job will be added at the end of the list of existing jobs, meaning with the lowest priority. Visual aids, like red diamonds for a due date not met, indicate, that the job cannot be delivered on time.

Now here the automatic scheduling functionality of just plan it comes into play: jpi provides you with the critical sequence number, this means the position in the list where the delivery of the job will be on time. In this sample, the planner can move the job from position 43 to position 18 in the list.

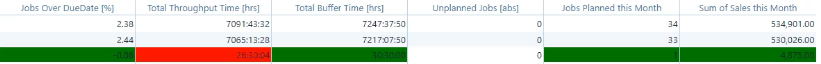

At the same time jpi scheduled everything that is associated or any other jobs that were part of that process. Plus, the system also shows if the repositioning of the job affects the due date of any other job in the job list.

Let's check the resource allocation: jobs with now lower priority have made way for the urgent job, allowing machine 334 to take over the CNC task on March 11.

There are also other parameters that jpi checks while rescheduling, e.g. if the rescheduling has a negative or positive impact on the throughput or revenues.

Want to see how to squeeze in the urgent job in the production schedule live, here you are: Dave, our production scheduling specialist, did a short recording of such a typical production scheduling use case.

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Machine shop scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think