Menu

There are various techniques to increase the efficiency of small businesses, such as aligning workplaces with lean principles, improving set-up times, optimizing external material supply, increasing flow. There is a wide range of consulting services and software available on the market. But for small high-mix low-volume manufacturing companies with up to 50 employees, these offers are oversized and their algorithms do not fit their special scheduling needs. Usually, these small manufacturers tend to use a simple Excel sheet to create a production execution plan that gives them at least a rough overview of orders, tasks, and delivery dates.

With a growing business, their key concern is to process the increasing number of orders with the existing team and equipment without their production hall descending into chaos. But sooner or later Excel reaches its limits and they have to look for a software solution that supports them in scheduling the jobs.

Which kind of software solution is suitable for these small, specialized businesses as they grow? This is what this blog post is about.

For HMLV manufacturers, the customer is king and customers love punctuality, reliability, and quality. These companies must be able to deliver their high-quality products on time, quickly calculate a realistic delivery date for quotations, and bring forward orders from jostling customers if necessary, without losing sight of quality. Customers usually also place their orders without much lead time. High-mix low-volume Manufacturers do not work with a long-term planning horizon, but with a very dynamic one.

Typically, the employees at the small producers are very flexible. Rarely are there machines or work steps that can only be operated or performed by a single employee. Their experience and their wide range of applications make the strength of the mostly family-owned companies.

In the early days of these manufacturing companies, the production plan can be kept more or less on schedule. However, with steadily increasing order volumes, both the human and the machine resources reach their limits.

Now comes the point where high-mix low-volume manufacturers are looking for suitable software to get a grip on their scheduling.

Not only are they in danger of alienating their customers because deadlines are not met. Their employees also are becoming increasingly frustrated because they have to constantly respond to unscheduled changes and work overtime. And, of course, cost pressures are forcing them to make their production as efficient as possible.

A complete ERP system is oversized and too expensive for such small companies. And the production planning tools of these solutions, with their optimization algorithms, are geared more to large mass products than to the needs of small HMLV producers.

The selection criterion for products for scheduling the production of HMLV manufacturers is, therefore: Keep it simple (see also: which production scheduling system is right for you?). The little helpers they are looking for should not control the whole production, but they should provide suitable planning support. These solutions must be easy to integrate, intuitive, and contain both manual and automatic planning functions.

The combination of three key areas brings the most value for HMLV companies when they are looking for production scheduling software.

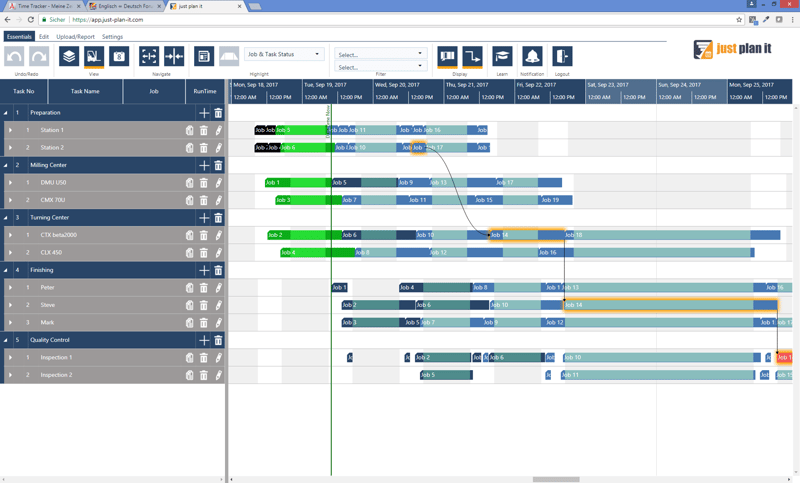

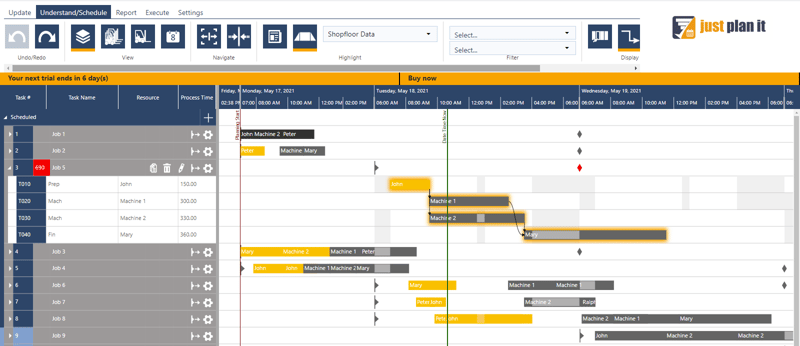

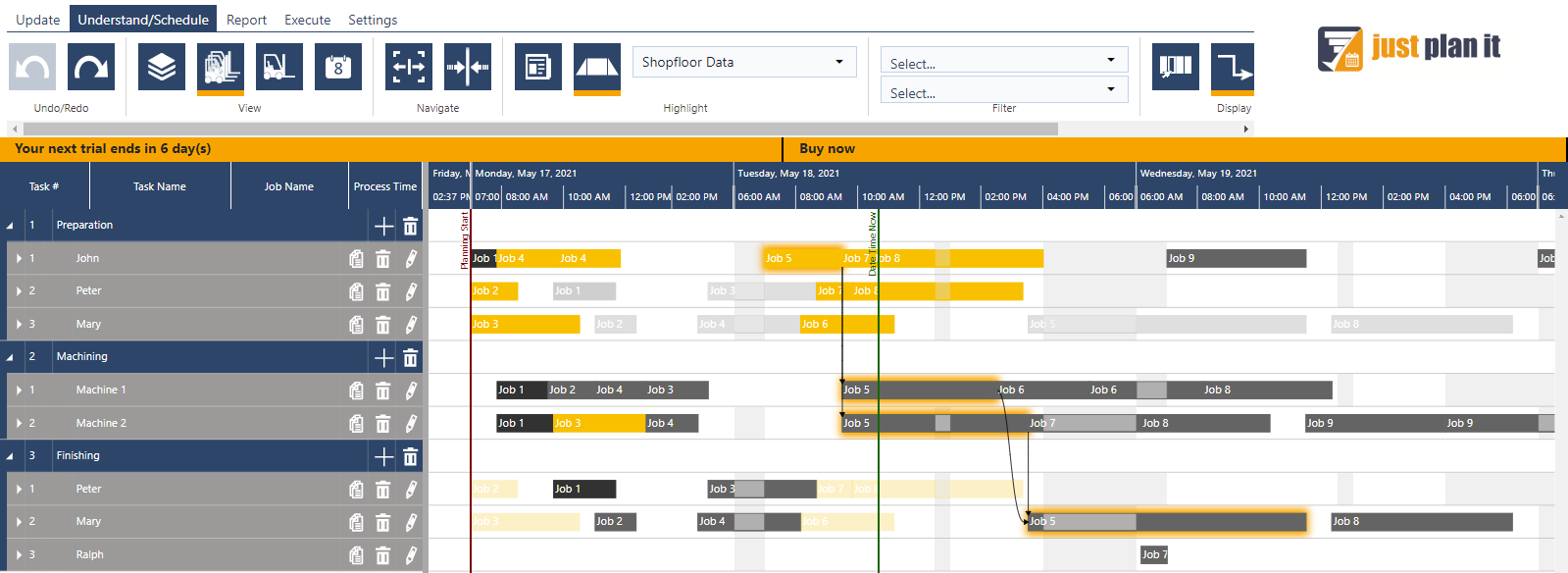

A visual, accurate production schedule in the form of a Gantt chart is the first important step in getting an overview of all the jobs, tasks, and resource utilization. Data that should come together here in the overview are:

See also: Which data are essential for production scheduling in HMLV job shops

This data should be prepared in at least two views. One that lists the orders with their individual operations, and another one that shows the tasks from the perspective of the resources.

The Gantt chart should not only be intuitive but should also offer a lot of visual decision support e.g. by visual warnings, providing relevant information at the right time and place, etc.

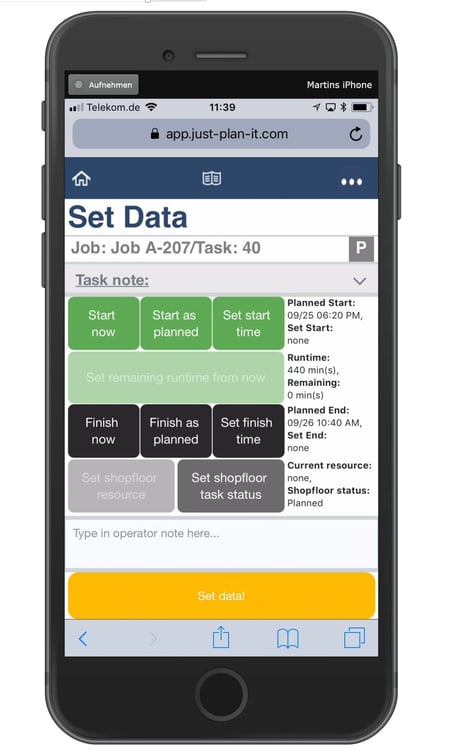

In addition to the overview, the function of feedback from the shop floor is essential: At the end of the day, the planner must know which task was completed and when, and which was not completed. This feedback must automatically flow back into the Gantt chart (and update the schedule automatically so that HMLV producers always can work with a current schedule).

Good planning tools for HMLV manufacturers are hybrid systems that combine manual and automatic scheduling. Why is that?

Abstractly speaking, these companies schedule the sequence of their orders using priorities. Whether it is for delivery date reasons, or rush order reasons, the planner always asks himself, which order from my list do I give the highest priority from a delivery date perspective? So the planner should be able to change priorities manually, but be supported by automatic planning when it comes to what impact this priority shift has on the other orders.

Thanks to the Gantt chart visualization he can see which orders will then be delayed and decide whether he can discuss a later delivery date with the customer or make up for the missing time by working overtime.

Ideally, the planning software also gives him suggestions as to where he can place the rush order on the priority list without violating other delivery dates.

This priority-oriented procedure does not only work with orders but also to quickly calculate a delivery date for quotations.

One aspect oftentimes is overlooked when it comes to introducing scheduling software. HMLV manufacturers suffer chronically from a shortage of time.

So they can't afford software where they have to invest a lot of time to get it to work. They have to put the new software solution into productive use immediately. The solution must be either easy to learn and intuitive, which is hardly possible with complex scheduling tasks, or have a well-supported introductory phase.

Avoid software products, where the vendor forces you into tedious, and time-consuming self-training. Look out for a software, where you are brought live fast, seamless, and with a kind of hand-holding approach.

just plan it has been developed exactly according to these principles and with the expert knowledge of HMLV manufacturers. Our customers achieve a 30% - 40% improvement in on-time delivery after just a few weeks. Just plan it can be controlled via Excel and is therefore an ideal tool to support small manufacturers in their growth.

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Machine shop scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

Comments (1)