Menu

For job shops, fabricators, manufacturers, producing a high variety of products in small quantities, the preparation of the production schedule is a highly complex daily challenge. There is no long-term planning, no consistency in the production process, and the sore point in production is the due date. It is quite clear that without any software support, as a digital graphical planning board, efficient scheduling of the production is impossible.

How can you tell if a digital graphical planning board is suitable for the planning and scheduling requirements of high-mix low-volume manufacturers?

Here are 10 key features that a digital planning board for HMLV manufacturers should offer.

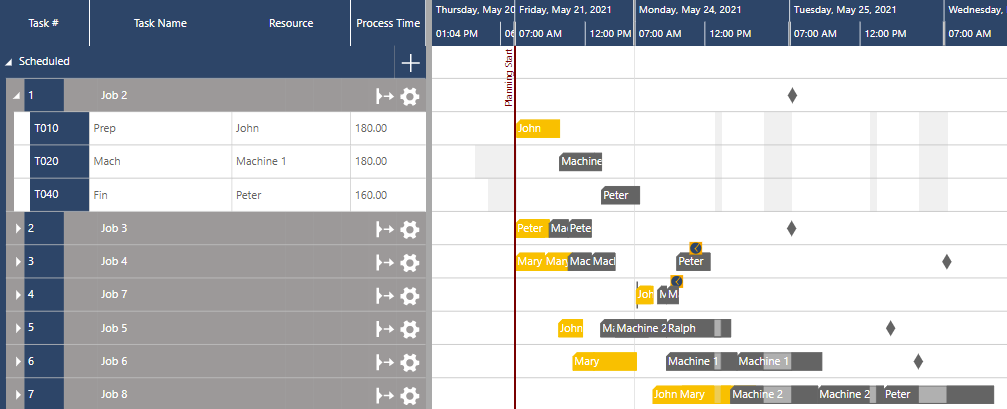

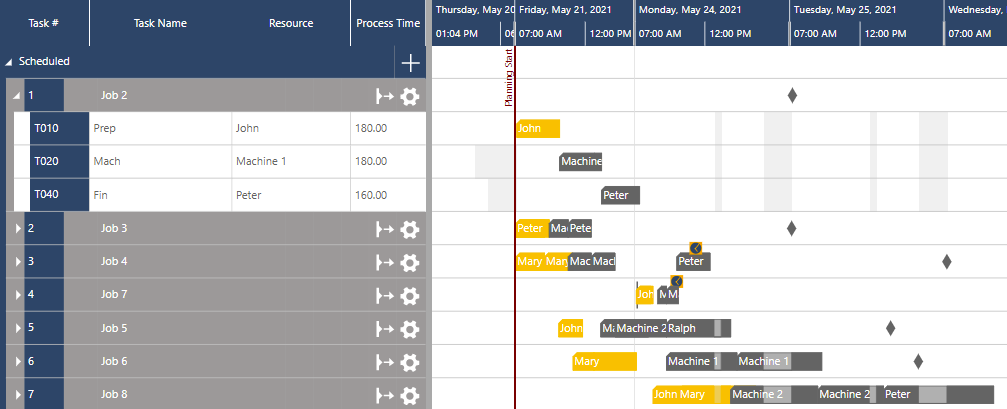

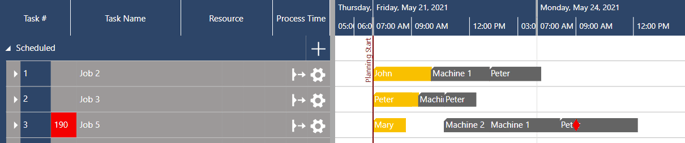

HMLV manufacturers usually list their orders. The newest order is added to the bottom of the list. In the table part of the planning board the jobs respectively orders appear with a sequence number and the order itself can be expanded and the individual tasks are displayed.

An important customer order has to be brought forward. Such rescheduling is the daily work for HMLV manufacturers. Manual intervention in the existing schedule, and thus in the planning board, is therefore required.

The basis of the planning board is a database. This can be an MES, an ERP System, or Excel.

When you manually change the schedule - if you, like in the sample above, change the priority of a job, or any other manual adjustment of the schedule has to be done, the original database of the planning board should be updated accordingly. Integration of the planning board by a bi-directional interface to the MES, ERP, or any other database is essential for up-to-date scheduling.

As you can see in the samples above there is always a need to manually adjust the production schedule on the shop floor. In a digital graphical planning board, a simple scheduling engine helps to quickly realize the change, e.g not only drag and drop one job with its associated tasks at a time but also re-scheduling the following jobs in the schedule (and making sure that you do not overload your machines downstream).

The sore point for small production companies is to deliver on time. The planner must be able to see this important information immediately in the plan. Therefore, visual signals must make exceeding the due date immediately visible.

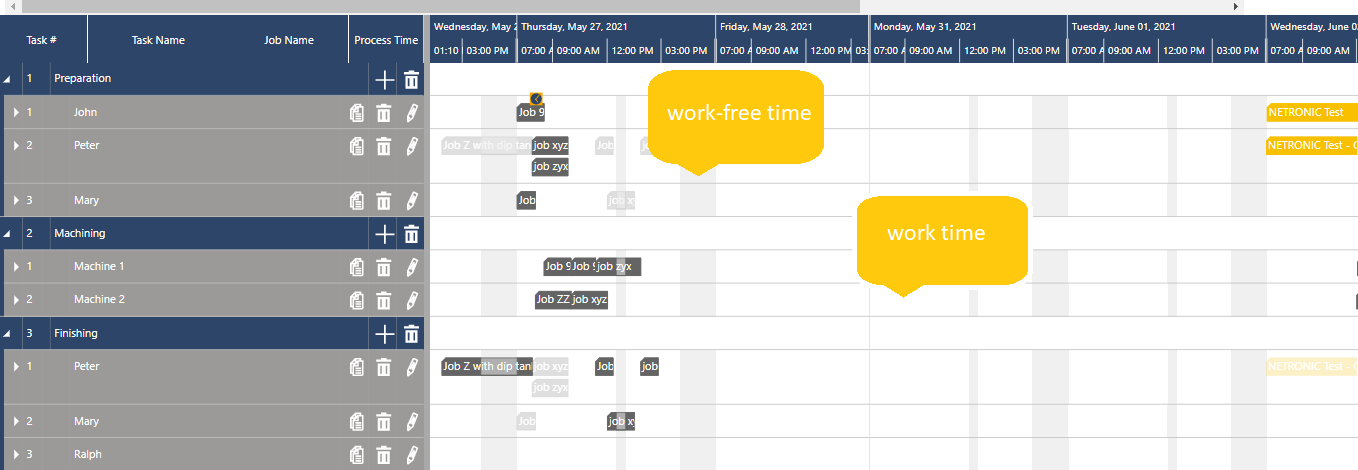

The availability of resources is, of course, a core element of planning. Whether human or machine, the working or non-working times must be recognizable in the planning board. This includes the calendars of each resource, as well as vacation times or maintenance intervals.

For machines, the task assignment is quite simple. A drilling line does the drilling, and a cutting machine does the cutting.

But this is different with the employees, especially in small manufacturing companies. They can usually be used for many tasks in the production process. These different employee qualifications must be taken into account when assigning them to tasks.

On the other hand, there are certain tasks that only a certain employee takes on because he has knowledge that the other colleagues do not have. Or the planner would like to primarily address a task to one specific employee. Then in the planning board, this "constraint" must be visible.

For the planner, the planning horizon he has to check, changes constantly. Sometimes it is a preview of what is already planned for the next few weeks, sometimes it is an hour-by-hour check of the daily schedule. With the help of a time scale that can be zoomed in and out with the mouse wheel, navigating the planning periods becomes easy.

What jobs have to be done and can I insert an urgent order in the schedule? How busy are my resources and what are they working on? Both perspectives are relevant for the planner and can be displayed in a digital graphical planning board by switching between different views, based on the same data.

There are, of course, other features that a digital graphical planning board should offer to improve scheduling efficiency in small businesses. But these 10 functions always evoke the reaction "yes, exactly this is what we need", when we present our production scheduling software just plan it to job shops :-)

Feel free to take a look at just plan it - a scheduling software specially designed for job shops or contact us to discuss how just plan it can make your production scheduling easy.

From 1 day to 45 min - how a US manufacturer schedules projects today

30% decrease in WIP with purpose-built software for HMLV manufacturer

Why using lean principles to improve high-mix low-volume facilities is not the first step to make

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Machine shop scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

No Comments Yet

Let us know what you think