Menu

If you run a high-mix low-volume machine shop, it is both challenging and indispensable to schedule your order backlog is a big challenge but indispensable. I've spoken with a very large number of production planners and job shop owners about scheduling. They all confirmed - without exception - that everyone is planning his shop floor operations in some way. That means: shop floor planning is seen as too important to be be left unmanaged.

Many people I spoke to also confirmed that they built their own "tools" themselves to cope with this challenge. In that regard, Microsoft Excel is by far the technological basis and starting point to create a home made capacity planning.

In this blog post I show you how to best use Microsoft Excel for capacity planning - and why this is also an appropriate first step to get going with job shop scheduling.

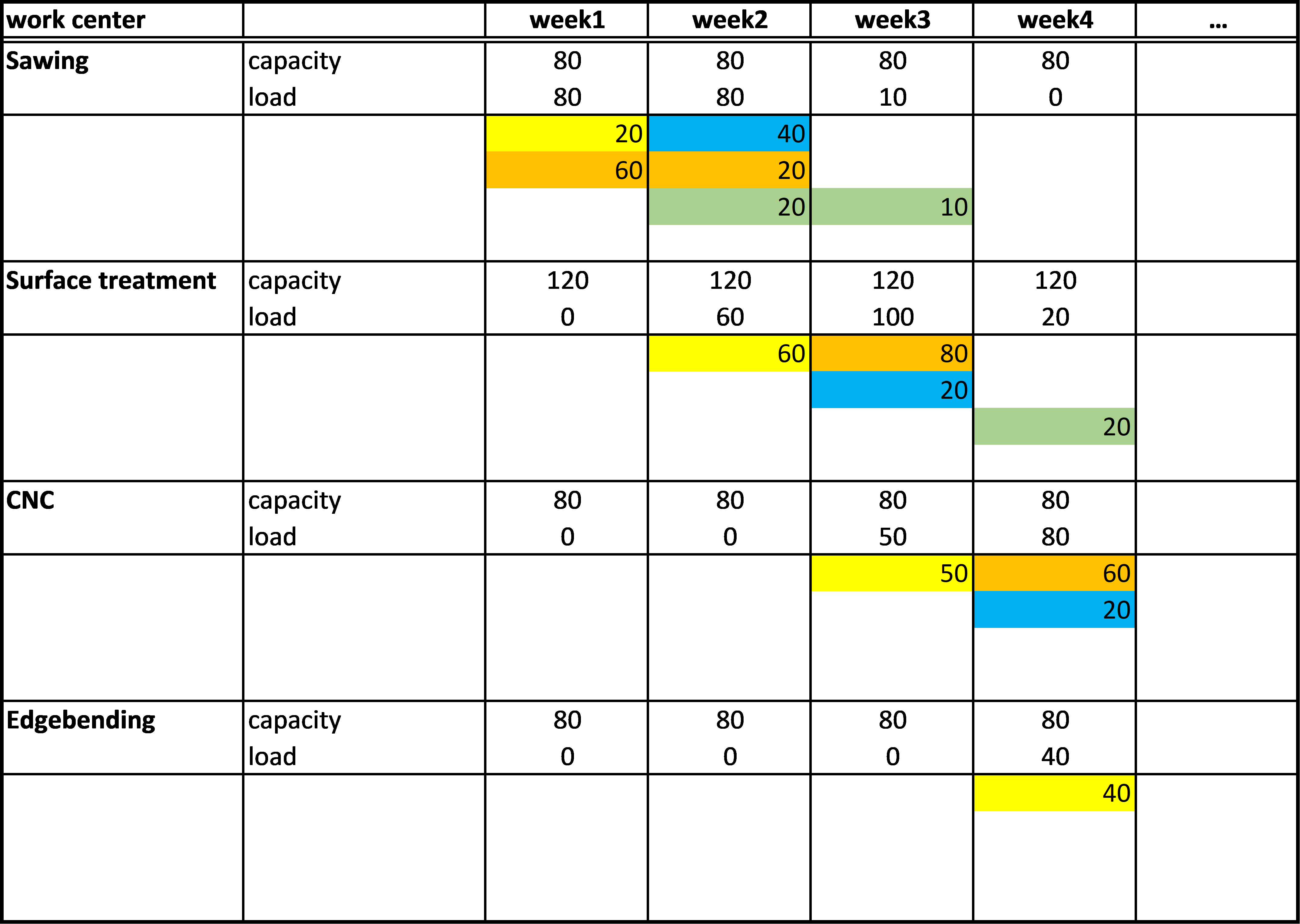

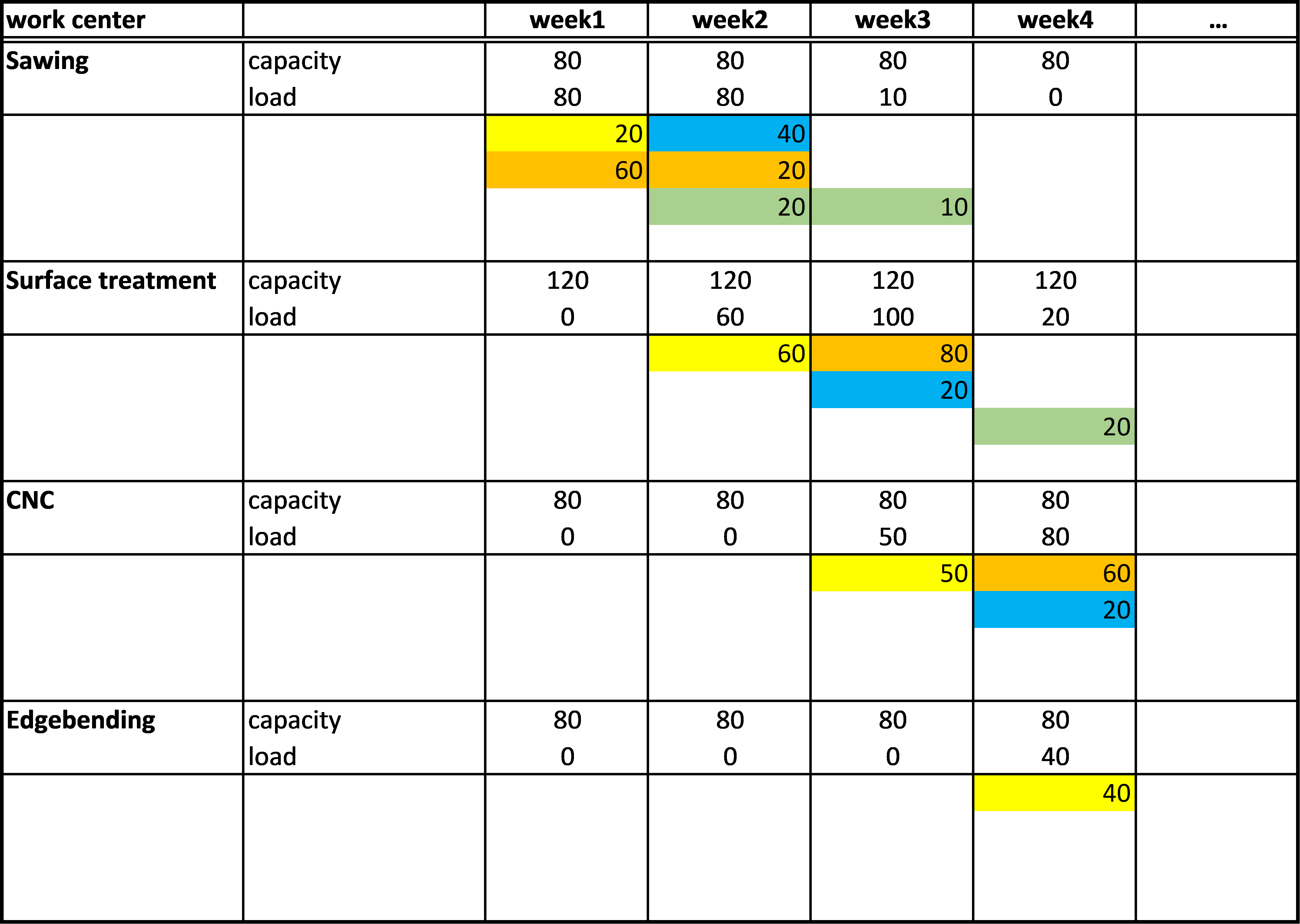

As Excel is a spreadsheet software, the structure forces the “planner” to think in timeframes. So the first step is to decide which period is represented by a column. The most preferred approach I have seen is “weeks”. Hence the capacity for work centers are defined and checked against the backlog on a weekly basis.

Let´s make an example: there is a shop with

The shop runs a one shift business with eight hours per day from Monday to Friday. Following the capacity of the week approach this results in following capacity per work center and week:

This is inserted into a spreadsheet accordingly. Then the backlog is “assigned” to the work centers manually while checking the overall capacity per work center.

Although this approach leads to a kind of plan, it has serious disadvantages compared to a real finite scheduling. Let's have a closer look the three most crucial issues among many others.

The inadequacies of this approach point the way to how to do it right. Finite scheduling starts with defining capacity of individual resources in two steps:

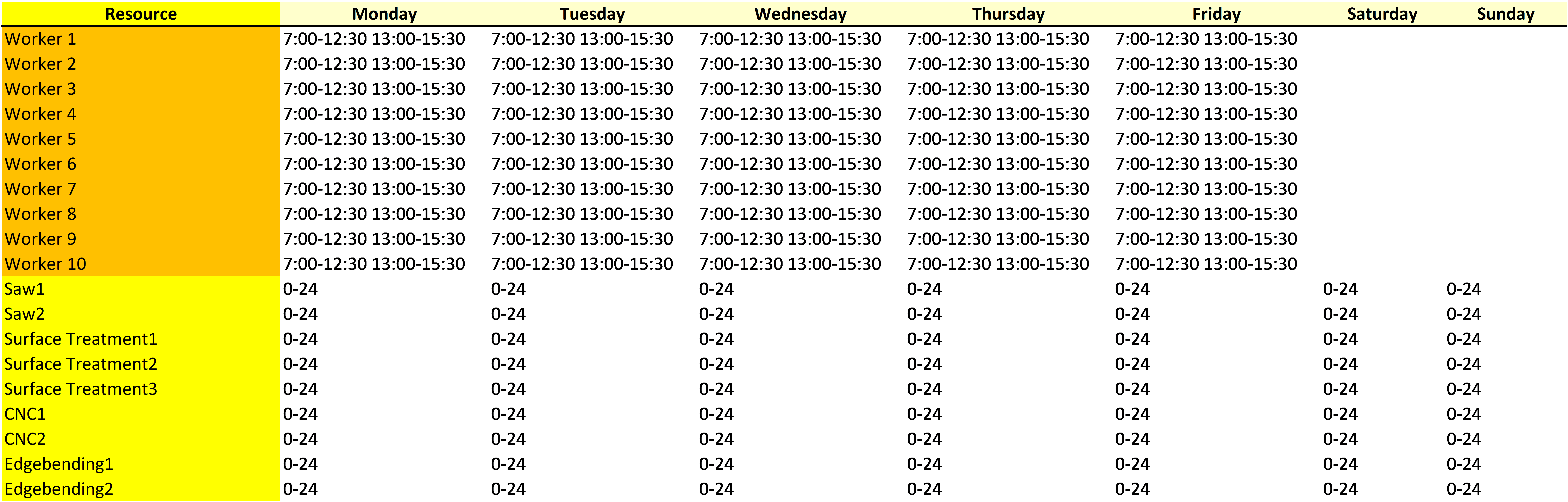

This is fairly easy. Just list every machine and every employee of your business that you want to schedule. Then define the standard availability per every weekday. If every machine task must be operated by one employee the machines can get a 24/7 availability while the contractual working times define the manpower availability.

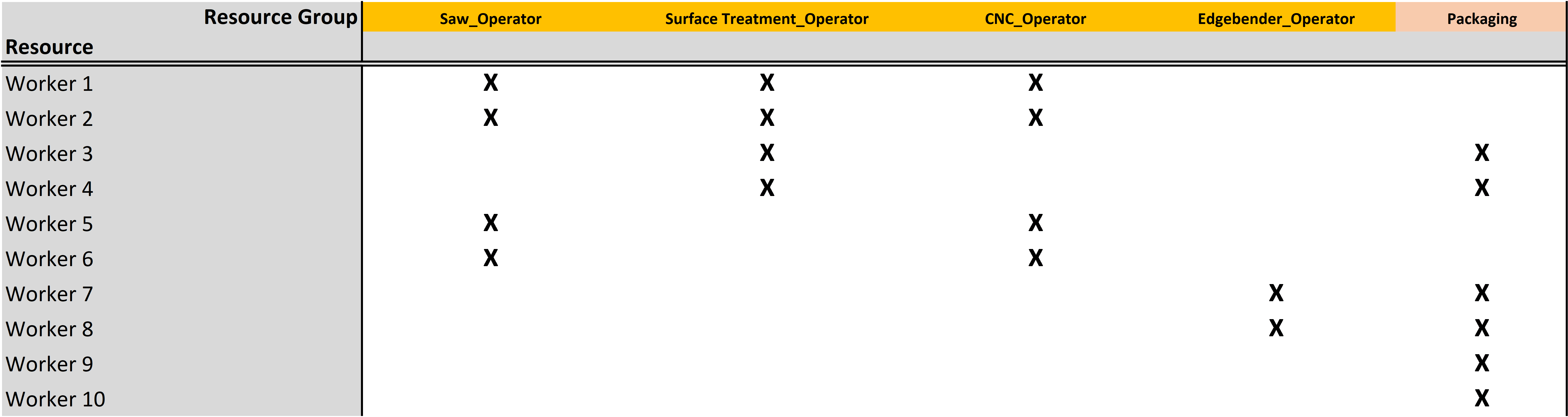

First, list all kind of operations where manpower is needed. Together with the list of resources of step 1 this spreads out a skill matrix, where you can define which of your worker is capable to operate which task.

Additionally you should also structure your machines in resources groups. Here, machine resources should be bundled that can be taken alternatively. So in the end spread out a skill matrix for machines also.

With this exercise, the most important step for successful finite high-mix low volume scheduling is done.

If you want to get going, download our Excel template for defining finite capacities.

Have a look into the video to see how easy this works:

PS: Want to learn more about job shop scheduling? Read our ultimate guide to visual job shop scheduling.

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Job Shop Scheduling

Made with by BOYUM IT SOLUTIONS GmbH (Copyright © 2024) Read our Privacy Policy & Terms of Service

Comments (1)