Menu

If I would be asked what I see as core element of almost any job shop, I would be tempted to say "constant change". A job shop's world is determined by a high variety of products which get manufactured combined with very small batch sizes. Orders typically are won short-term with the customer requesting a quick delivery. As change is the one constant in a job shop's day-to-day business, also the schedule must get changed constantly. Typically, job shops start managing their schedules with manual systems such as whiteboards, paper or Excel-based scheduling approaches. However, sooner or later they recognize that these systems are unable to cope with the constant change of their business. Hence, job shops face the need to introduce some kind of scheduling software. This blog post provides eight must-haves of any job shop scheduling software.

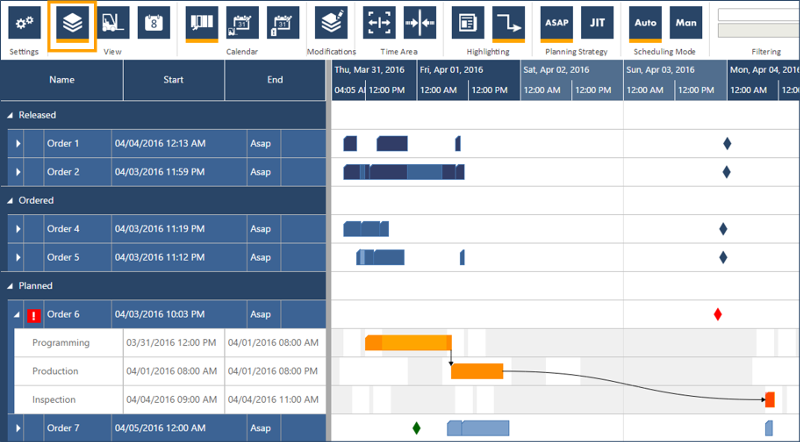

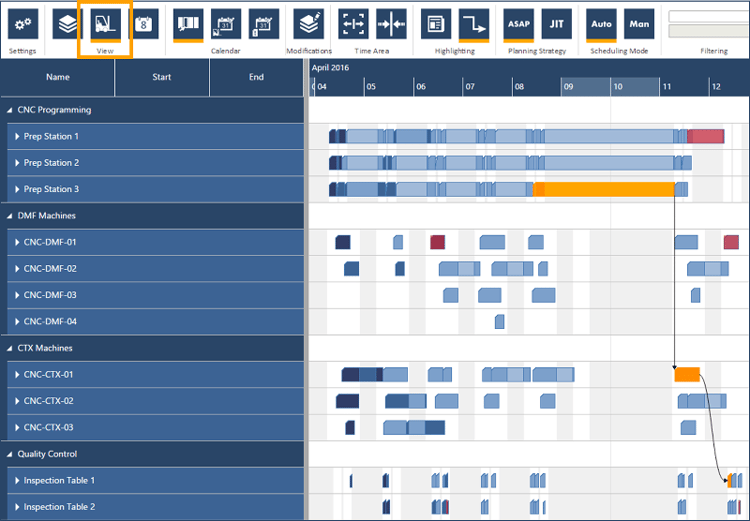

Many software applications seem to be built from the perspective of the data, rather from the perspective of the user. Undoubtedly, the most efficient way to handle data from a technology point of view is a database with its rows/columns-oriented structure. Hence, it seems to be no suprise that many scheduling applications feel like being a kind of "logical frontend" to a database. These applications provide the schedule in tables, structured in rows and columns and showing data as figures, dates and numbers. As practical as this seems to be, I always recommend not putting technology in the core of an application, but the user. Hence, especially in an ever changing environment, the schedule should be presented in a visual way and the user should be enabled to see changes at one glance (rather than having to search them and feeling to be a kind of "data detective"). Well, I would even dare going a step further. The visual bit should not just be a feature of the application, but it should be the foundation of any job shop scheduling software.

Many software applications seem to be built from the perspective of the data, rather from the perspective of the user. Undoubtedly, the most efficient way to handle data from a technology point of view is a database with its rows/columns-oriented structure. Hence, it seems to be no suprise that many scheduling applications feel like being a kind of "logical frontend" to a database. These applications provide the schedule in tables, structured in rows and columns and showing data as figures, dates and numbers. As practical as this seems to be, I always recommend not putting technology in the core of an application, but the user. Hence, especially in an ever changing environment, the schedule should be presented in a visual way and the user should be enabled to see changes at one glance (rather than having to search them and feeling to be a kind of "data detective"). Well, I would even dare going a step further. The visual bit should not just be a feature of the application, but it should be the foundation of any job shop scheduling software.

Next thing: if you agree that "constant change" is the criteria which best characterizes a job shop, you will be not surprised if you hear me saying that any job shop scheduling software should enable the user to easily change the plan. If your business is constant change, and if you are not able to change the plan when needed, you simply cannot run your business. So, what does "easily change" mean?

Let's combine #1 and #2. If you manage to build and maintain your job shop production schedule in a graphical way, you should be able to change the schedule via drag and drop. Just grab the bar (representing a task) with the mouse, and it move it to change the time. Job shop production scheduling can be as easy as this.

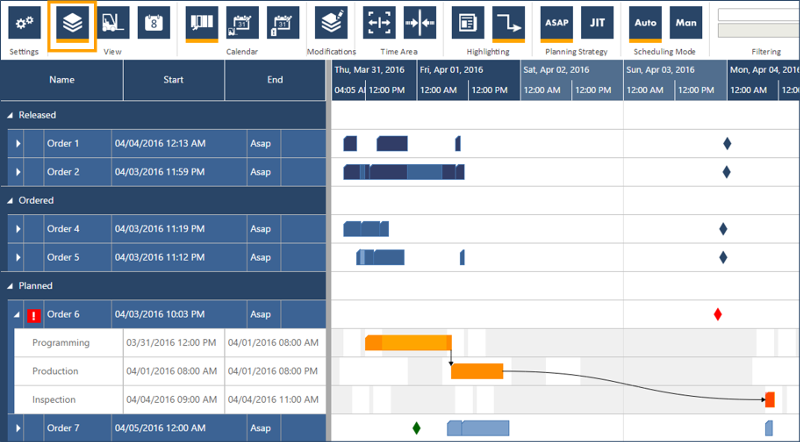

Great. Now you have a visual job shop schedule, and you are able to quickly change jobs and tasks via drag and drop. Already this is much better than any production scheduling "system" based on Excel or on a whiteboard. But, wouldn't it be much better if there would be some kind of scheduling intelligence which supports you with your rescheduling tasks, or which makes it easier to compare some scheduling scenarios? This intelligence - at least - should take into account the following when working with a job shop scheduler:

Again: these are simple rules. They are hands-on and easy-to-understand. Based on my experience from many customer projects, they perfectly fit with the needs of job shops and small make-to-order manufacturers.

Now it gets tricky. I know that before moving to a job shop scheduling software, many job shops built their own scheduling "system": sometimes manual and paper-based, sometimes manual and with a big whiteboard, and quite often with spreadsheets such as Microsoft Excel. Using Excel to start with operational production planning and scheduling typically isn't a bad idea, and typically brings some substantial quick wins. However, there are also some substantial limitations to this Excel-based scheduling approach - especially when your business lifts off.

This is a dilemma: you have an Excel-based scheduling system to which are used to. But this system does no longer support your growing business. That means de facto, that this system starts hurting your business. Hence, you need to act fast and move to a scheduling software beyond Excel. However, learning something completely new typically never is fast. So, make sure that your job shop scheduling software easily integrates with what you know best: Microsoft Excel.

As job shop or make-to-order company you live from your great customer relations, and from your ability to deliver on time. I assume you are familiar with the following scenario: your schedule for the next two weeks already feels rather busy. Then you take a call from your top customer requesting an urgent job to be completed mid next week. What happens to the other orders if you squeeze this in? What can you do to keep the requested date?

Finding answers to these questions should be the focus of your machine shop scheduling software. It should put the task of keeping delivery times under control in the focus, and enable you to manage the super urgent order.

However, just focusing on jobs, their tasks and their delivery dates will not fully do the job. The jobs/order-centric view should be complemented by a machine/resource-centric view which helps you understand the machine utilization on one glance. For sure, a proper scheduling takes care of no overbookings to happen. But assume that one machine breaks down unexpectedly: In that case, you can easily see spare machines and reallocate the task accordingly.

Let's state the obvious: as job shop or as small make-to-order shop, you do not have a bunch of IT folks working for you. In fact, it is fair to assume that you have no dedicated IT staff at all, and that either you take care of all IT questions yourself or that you have a person to whom you outsource the most imminent IT tasks. I would even not be surprised if this lack of IT knowledge might be one of the strongest reasons why you still manage your job shop schedule with Excel, and why you are shy investing in a proper software solution. Here is the good news: state-of-the-art cloud-based software applications do not require any installation, and they can be run without employing lots of IT folks. They are ready-to-use: just visit the respective website, request a trial account and get going - from your browser. Easy peasy.

Last but not least, there is one important technical aspect to take into accout when looking for a machine shop scheduling application. This is related to the question which technology-originated limitations you face using the software. For example, a Windows application always requires a Windows PC to be worked with; you cannot use it on a Mac or an Android tablet. So if you want to have anytime and anywhere access to your scheduling application, independent of your hardware and independent of the operating system that runs this hardware, you need to look out for a platform-agnostic application. The only software code that truly allows this is code written in JavaScript and HTML5 technology.

So now that you know eight must-haves of any job shop planning software application, why not taking a closer look at just plan it? It was built with these eight fundamentals in mind. Come on: let's get on a call with one of our scheduling specialists and tackle your production scheduling challenges.

just plan it is a production scheduling software plus scheduling tools & best practices to help high-mix low-volume make-to-order manufacturers gain transparency and control over their shop operations. The software plus its methodology is used by thousands of people around the globe. They consistently achieve improved on-time deliveries, shorter lead times, and better utilization of their resources.

As just plan it is not just software, but a lot of processes and best practices, we recommend that you start with an exploratory meeting. If we agree that there is a fit between your requirements and our approach, we'll build a prototype for you.

Hence, it all starts with a meeting. Book that meeting now.

These Stories on Machine shop scheduling

Made with by NETRONIC Software GmbH (Copyright © 2019) Read our Privacy Policy & Terms of Service

Comments (7)