Following the debate about all the different scheduling approaches it is inevitable that you are faced with two kinds of conceptuality: “flow shop scheduling” vs. “job shop scheduling”. The final intention of this blog is to give an understanding that the scheduling challenges and approaches of both worlds are so different, and why this is the case.

Therefore I first point out the different characteristics of flow shops and job shops as such. Based on this I derive the differences that come along with this in terms of scheduling. Finally, I give an outlook on what impact the differences have on tools to productively schedule flow shops and job shops.

How to characterize a flow shop and a job shop?

The first look into the current debate gives you a rough – because short – definition of both kinds.

Flow shop - short characterization

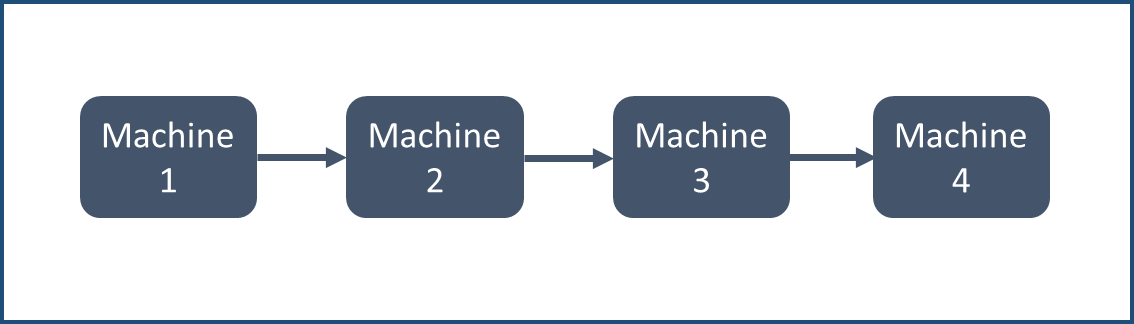

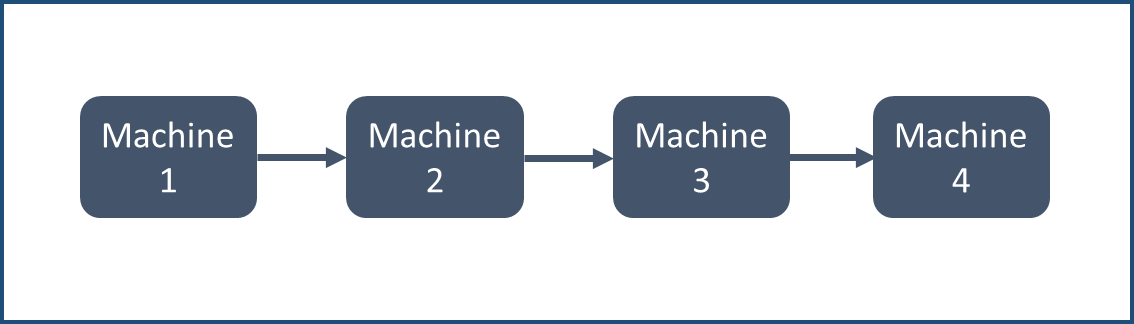

In a flow shop, the manufacturing process follows a fixed linear structure. That means that all orders need to be manufactured in the same way on the same machines.

Job shop - short characterization

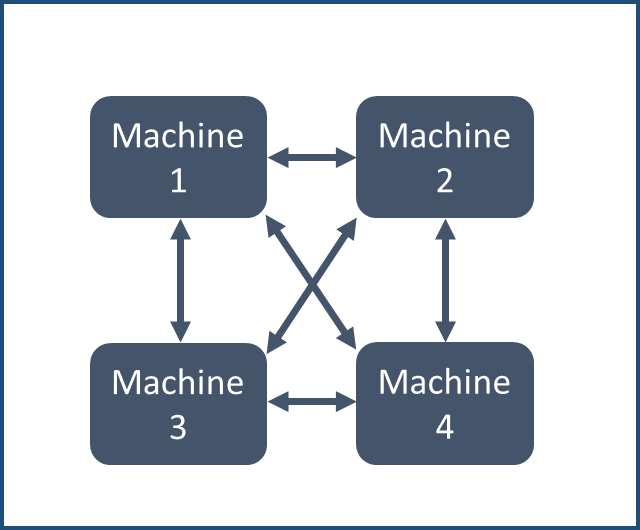

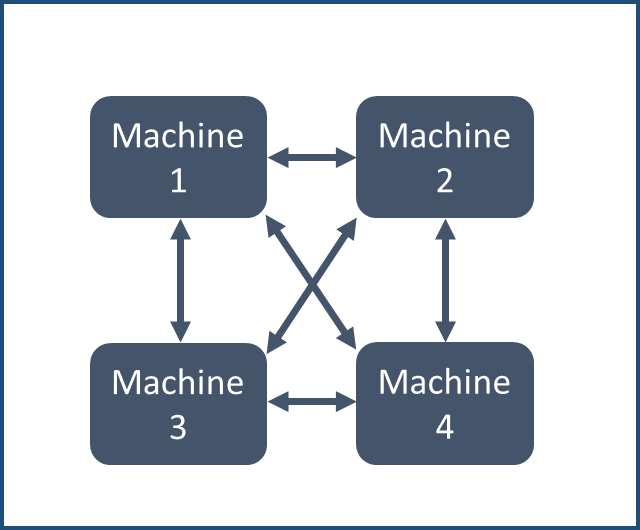

In a job shop, the routing of each job can be individual. That means that all orders (potentially) need to be manufactured differently on the same machines or a certain part of the same machines.

This gives a good first impression of the significant diversity of both manufacturing environments.

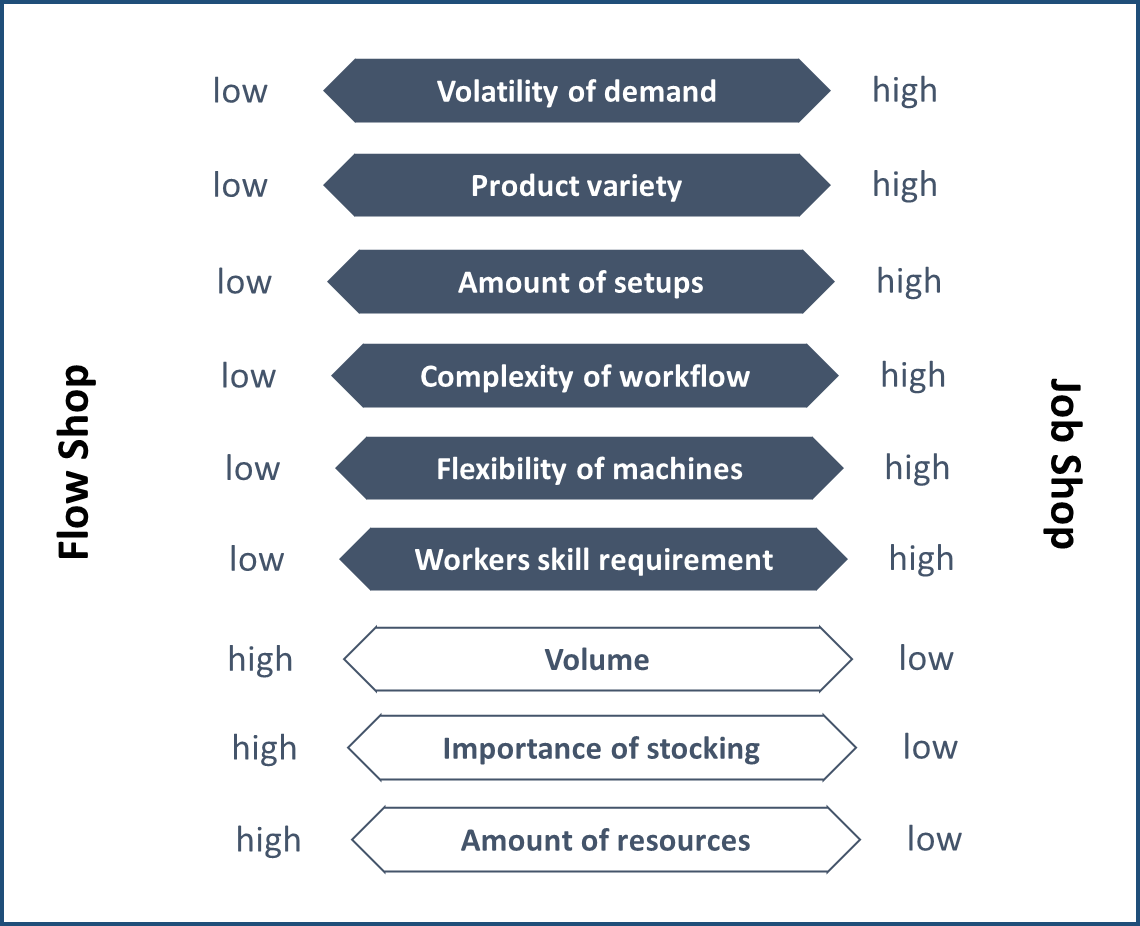

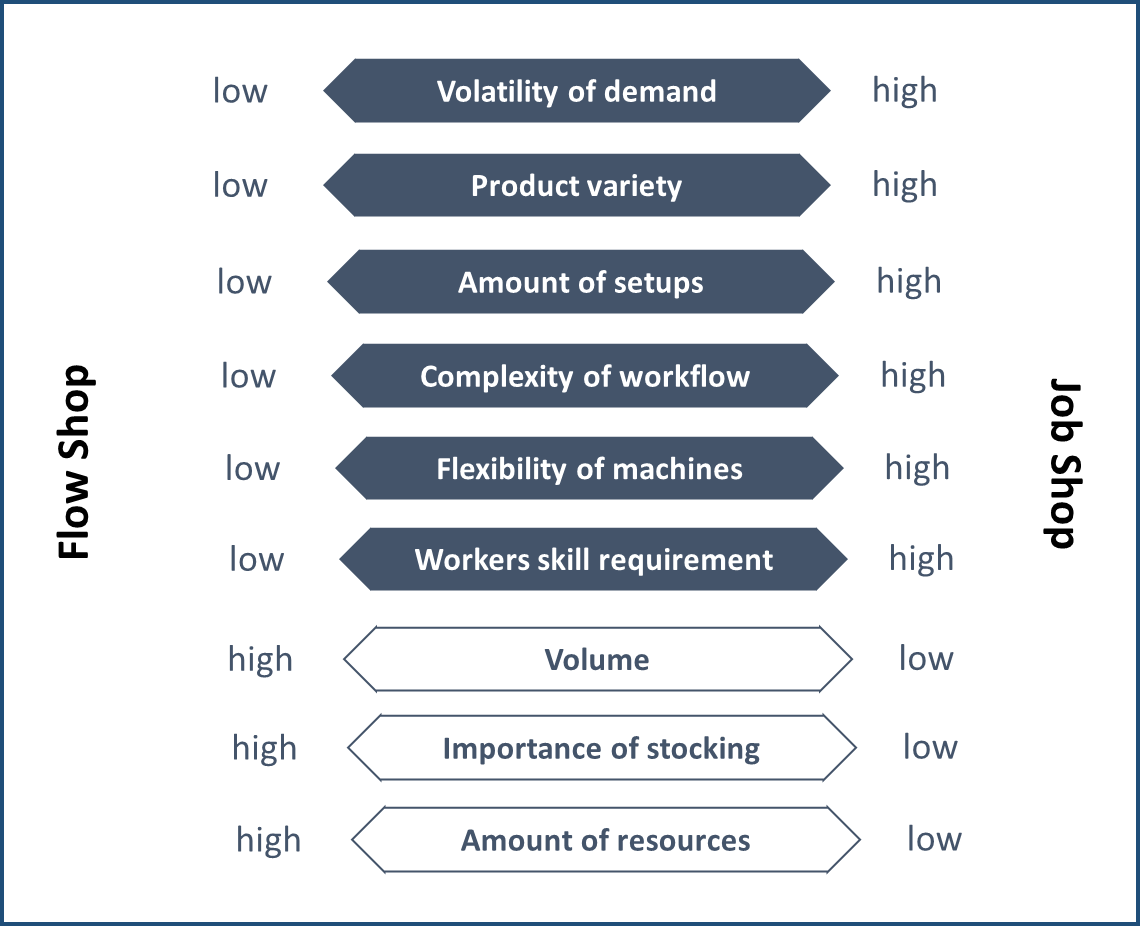

But in my eyes the best way to fully comprise the diversity, it is very useful to further characterize a flow shop and a job shop based on common criteria of the manufacturing industry.

To keep this as easy to understand as possible in the following I refer to the most extreme forms of flow shops and job shops possible.

In terms of a flow shop, this would be a manufacturing site with 100% standardization operated in an assembly production line. On the other hand, a job shop would be a business with 100% customization with a typical batch size of 1, which implies that every finished product is unique.

Characteristics to differentiate flow shops and job shops

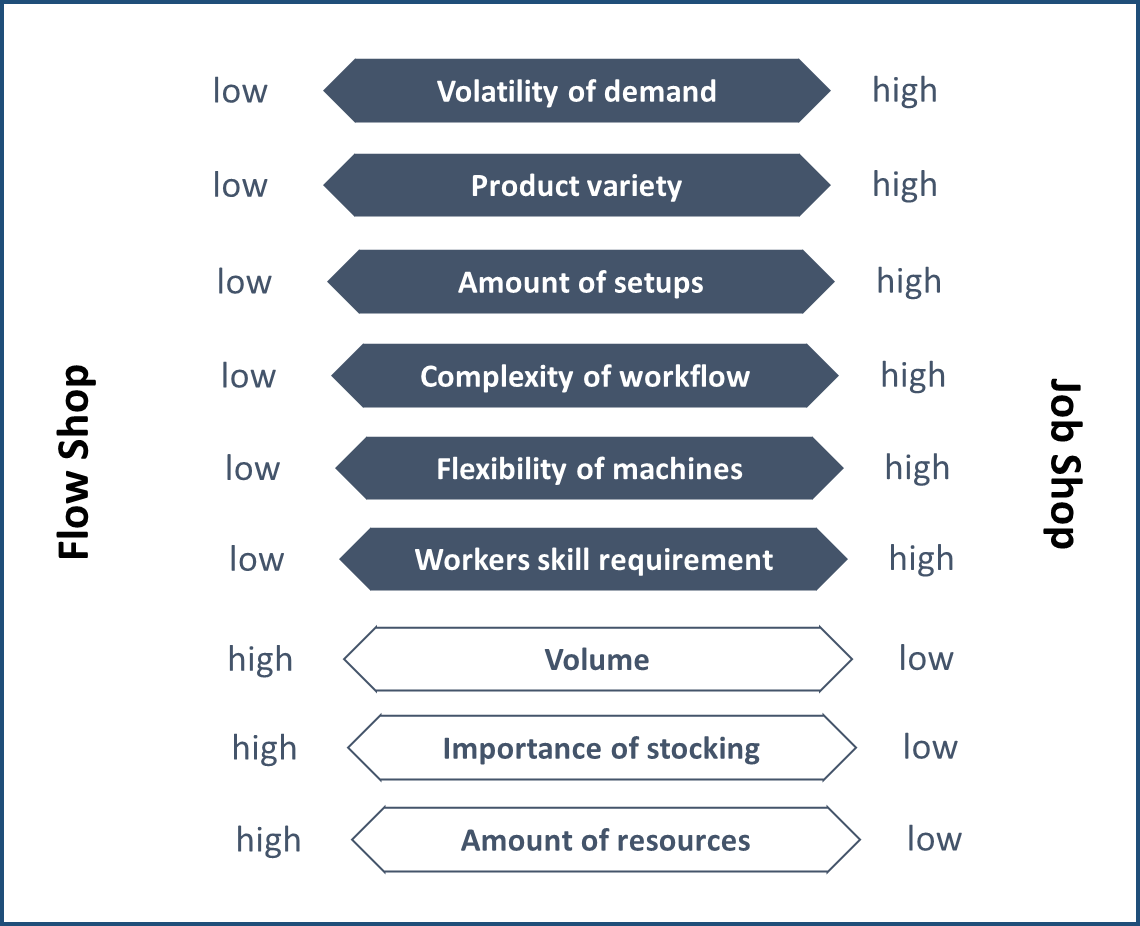

Volatility of demand

- Typically the demand in flow shops is steady and predictable. This means that the volatility of data is low.

- On the other hand, the demand in job shops is not as predicable at all but depends on the irregular occurrence of customer orders. So the volatility of data is very high as the environment is very dynamic.

Product variety

- The product variety in flow shops typically is low as there are just a few – and very standardized – products in the portfolio.

- On the other hand, the variety of products in a job shop can be – literally – unlimited. Hence the standardization is lowest as the added value of the business comes from the ability to customize.

Amount of setups

- In this sense setting up machines does not take place very often in flow shops as there is not a high variety of products and as there is the possibility to “easily” bundle equal operations into one batch to maximize capacity utilization.

- On the other hand, setups are necessarily daily business in a job shop as a result of the high customization and the focus on on-time delivery of customer orders.

Complexity of workflow & plant layout

- As the initial definition implies the workflow of a flow shop is simple because linear and standardized. As the processes are stable and predictable plants of a flow shop are structured in lines or following fixed work cells. That means that the spatial arrangement of machines is following the linear flow structure.

- On the other hand, the workflow of a job shop is complex because different for every job. There is even a quite high likelihood that the workflow of a job shop can change during the execution. Hence a job shop layout is structured functional. This means that a job shop is divided up into certain work centers that are capable to fulfill the same operation alternatively.

Flexibility of machinery equipment

- In a flow shop, the machinery equipment is geared to operate low flexibility due to the high standardization.

- On the other hand, job shop machinery is imperatively geared to be highly flexible due to the high customization.

Workers skill requirements

- In a flow shop, the skill requirement of the employees is quite low. The high standardization does not require highly educated workers. Also, it is quite likely that workers are firmly assigned to certain work cells within the manufacturing process.

- On the other hand, the skill requirement for operators in a job shop is comparably high. Furthermore the likelihood that educated operators have the skill to operate several different machines within different work centers is also very high.

Volume

- The volume – means the total output of units of end products in a given time window – of a flow shop tends to be high.

- On the other hand, the volume of job shops is comparably low.

Importance of stocking policy

- In a flow shop stocking is a core aspect of successfully running the business. This means that make to stock production is the default way of managing the production.

- On the other hand, the strategy of job shops is mainly make-to-order driven. Due to the high level of customization holding up stock is not a productive approach.

Amount of resources & company size

- Flow shop companies tend to be bigger in terms of employees, machines, and revenue.

- On the other hand, job shops are comparably smaller in terms of employees, machines, and revenue.

The graph below sums up the diversity of flow shops vs. job shops:

As we now have an understanding of the significant differences of both manufacturing environments the next step is to evaluate what impact the diversity has on scheduling.

Or in other words:

What does this mean for scheduling a flow shop vs. scheduling a job shop?

If we translate these characteristics into scheduling requirements it is obvious that flow shop scheduling and job shop scheduling also differ significantly. Let's start again with handy summaries:

Flow shop scheduling - short characterization

As the required data is not volatile and the planning environment is very stable and not dynamic, reliable input data can be generated. This is true for the demand as well as for the duration of operations.

In the case of an assembly production line, the challenge of scheduling can even be boiled down to optimizing the cycle time of how the line moves forward. In general, the output of flow shop scheduling is when to operate which task in which batch size.

To calculate such a schedule mathematical heuristics (like a genetic algorithm or simulated annealing) are very appropriate and common approaches to find the optimum solution for the given planning field. The respective - centrally determined - occupancy plan is then the firm instruction for the shop floor.

Job shop scheduling - short characterization

As the planning environment of job shops is not stable at all but very dynamic the estimation of planned duration comes along with a high degree of fluctuation. Furthermore, the demand is not calculable upfront as it is 100% customer order-driven.

So mathematical approaches are not appropriate as the high inaccuracy of the data would only pretend to deal with an optimum. Also, the ongoing need to reschedule due to daily incidents makes the flexibility to easily deal with this dynamic more important than the calculation of an alleged optimum.

The consequence is: for job shops visual scheduling approaches with automated scheduling support are most appropriate to answer the dynamic and productively generate schedules that then serve as a guideline for execution.

This again gives a good overview of the significant diversity of the scheduling challenges of both manufacturing environments. To work out the individual differences even more precisely, I now analyze the following based on common planning parameters.

Planning parameter to compare flow shop scheduling and job shop scheduling

Scheduling targets

- Due to the stable situation, maximizing the machine capacity utilization is likely the highest prioritized target of flow shop scheduling and simultaneously leads to the highest throughput possible.

- In job shops scheduling is mainly order focused. This means that on-time delivery is the highest prioritized scheduling target while idle times of resources in certain time windows even can be intended.

Visibility

- As the workflow is linear in a flow shop visibility is pretty much given automatically.

- This does not apply to a job shop at all. As routings can be all individuals, it is very hard for the planner to gain visibility. Or in other words: getting visibility of the shop floor activities is the key to successful job shop scheduling.

Generating planning data

- The demand for a flow shop can be derived based on evaluating historical data statistically. The same applies for quantifying the duration of operations.

- Estimating durations for the several – highly customized – operations is a core challenge of job shop scheduling. The evaluation of past data is helpful, but additionally bringing in the individual experience of the production planner is even more essential, and generating planning data generally is a process of continuous improvement.

Planning horizon & planning accuracy

- The predictability of data determines the planning horizon of flow shop scheduling. This can easily be one year. The planning accuracy has the same (high) level within the entire planning horizon.

- The order backlog determines the planning horizon of a job shop. This is most likely less than one year. Furthermore, the planning accuracy differs in the schedule of a job shop: due to shop floor progress information, the accuracy in the very short run is higher than for the rest of the schedule.

Capacity of employees

- In a flow shop, the shop floor manpower can most likely be disregarded, and scheduling can be based on the assumption that unlimited/sufficient manpower is available always.

- This does not apply for job shop scheduling. Here the shop floor workers' capacity is a limiting factor and must be considered in scheduling as well as the machine capacities. The normal case to schedule a job shop operation is to find the best available combination of a needed machine and a worker that has the skill to operate it.

Strategy of execution

- The favorable planning environment of a flow shop allows following a top-down approach of execution. This means that the given schedule serves as an irrevocable basis for the operational execution. The shop floor gets just a minimum scope of making its own decisions.

- The dynamic environment of a job shop makes it essential to authorize the shop floor in making decisions in the short run. Hence the schedule should always function as a guideline including a productive range of making decentral decisions. Furthermore, the progress of the shop floor must be integrated into the schedule regularly as the dynamic progress of one job has a significant impact on the entire schedule and all other jobs.

Importance of MRP (material requirement planning)

- As a flow shop is mainly make-to-stock driven the availability of material and especially the level of stock of semi-finished goods to balance the demand of production stages is a very important aspect of scheduling. Hence material requirement planning like BOM-orientated backward termination of material requirements as well as productively managing stock level form an essential symbiosis with the actual scheduling process.

- As a job shop is mainly make-to-order driven material and stock do not have the same importance. In general, the demand for material can be directly derived from the income of the customer order.

To wrap up the scheduling requirements:

The planning environment of a flow shop can be designated to be more favorable due to the stability of the decision-making field. On the other hand, the planning environment of a job shop comes along with more dynamic and more complexity.

What does this mean for scheduling tools for flow shops vs. job shops?

As written above flow shop scheduling can be described in mathematic models, that – fortunately – are solvable with modern technology. So flow shop scheduling tools consist of a heuristic engine that is capable to consider all flow shop parameters and then calculate the optimum of the given input.

Specifying a scheduling tool for job shops is not as favorable and finding an appropriate scheduling solution can be a herculean task.

But because of the knowledge gained from this blog post, the following four requirements must be met to successfully to face the special challenges of the job shop environment:

- Visual approach: to gain the visibility it is a must that a scheduling tool has a component that visualizes the schedule. Gantt chart oriented planning board applications prove to be particularly successful.

- Flexible & easy to use: the software tool needs to enable the planner to easily change the schedule to effectively fight the ongoing incidents.

- Automatic assistance: due to the high complexity a purely visual approach with drag and drop only would not be sufficient. Hence a scheduling engine that automatically considers all job routing structures as well as the given finite capacity – manpower & machines simultaneously – is also an essential feature of an appropriate job shop scheduling tool.

- Execution functionality: tracking the shop floor progress and easily bringing it into the schedule regularly is a must. Furthermore, this needs to include the ability of the shop floor staff to have space for decentral decisions.

And, if you still do not know how and where to start: Here is a blog post how to successfully start with job shop scheduling.

In summary, it can be said that flow shops differ so significantly from job shops that one can even speak of diametrical opposites. This contrast is not only noticeable in the comparison of characteristics, but also concerning the planning parameters.

Also it becomes clear that the requirements of job shop scheduling are much more extensive and complex to handle. While flow shop scheduling can be done by a mathematical algorithm, job shop scheduling essentially requires to consider the human factor.

No Comments Yet

Let us know what you think