As a SMB manufacturer or small job shop owner, few aspects of your day are more important than throughput or, in other words, your ability to move your jobs and their tasks through your shop effectively as to meet your delivery due dates.

So, what happens when your delivery due dates are threatened by delays as a result of bottlenecks?

If on the one side the sum of runtimes should allow you an on-time delivery and your schedule on the other hand indicates a delayed planned end, you can be sure that you are facing a bottleneck. It implies that certain tasks of your job need to wait for a resource even though they would be ready to be processed immediately. These waiting times originate in higher priorities of other jobs that are processed first.

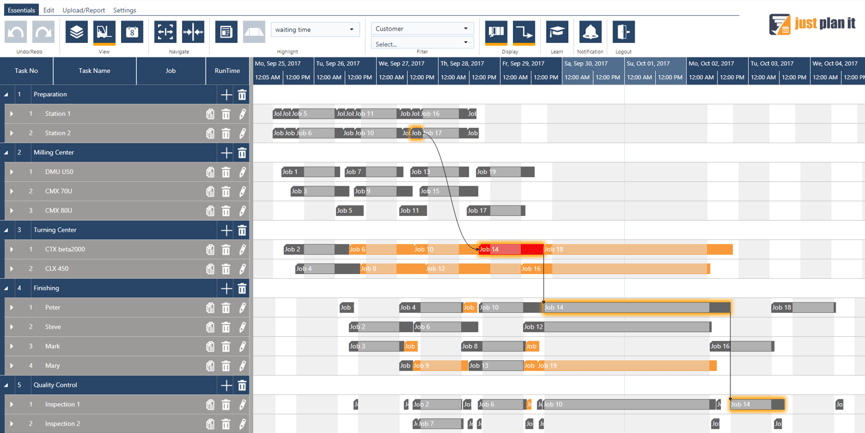

So, to effectively fight bottlenecks it is essential to see where they are in your schedule. To spot waiting times in general and bottlenecks in particular, just plan it provides a special color scheme. It displays tasks with waiting times in orange and tasks with waiting times that also belong to overdue jobs in red so that they can be recognized at one glance

Following the theory of constraints the key of optimizing production is to focus on bottlenecks. In our example it is obvious that the Turning center is a bottleneck in the given timeframe. Consequentially you should increase Turning-capacity to increase the throughput of your schedule and fight the delay of Job 14.

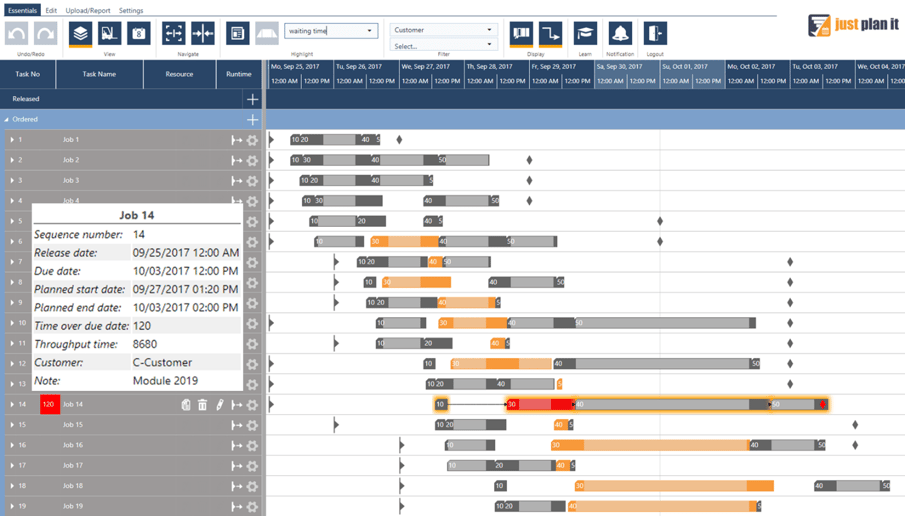

To get an idea of how much you need to increase the capacity you have to have a closer look into the Job view of the current schedule of the delayed job: It tells you that the job is delayed by 120 minutes.

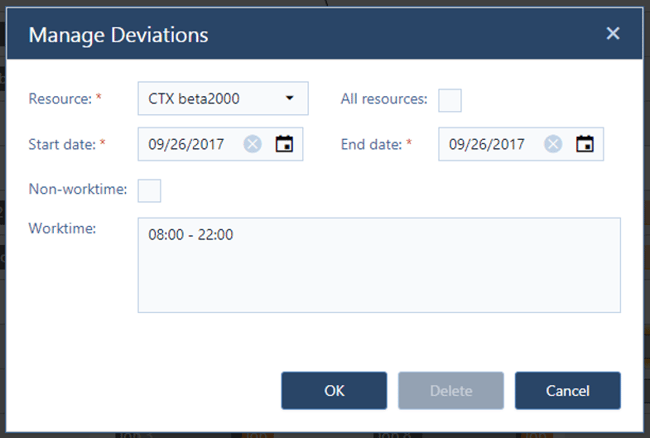

So the action to take is increasing capacity of the bottleneck resource CTX beta2000 by a minimum of 120 minutes. If you plan this extra shift within the timeframe of the first task with waiting time, this will have a positive impact on most jobs. Planning extra shifts in just plan it is very easy. Just define a deviation to the standard calendar.

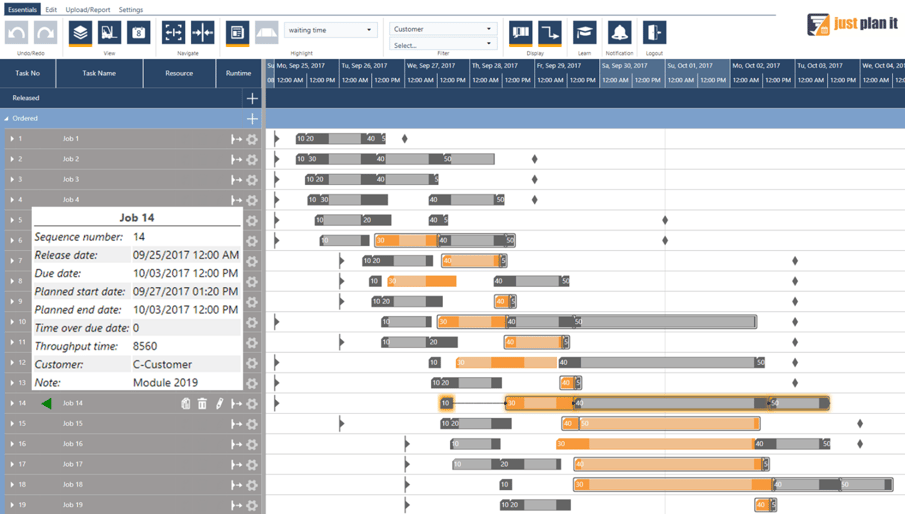

After activating this deviation, the just plan it scheduling engine automatically calculates a schedule including the new capacity. So the extra shift is filled with task load and also all other tasks concerned are automatically moved „leftwards“.

Finally you can kick off the job and release it to the shop floor and execute it as planned in your schedule.

Interested in more use cases? Learn how to get rid of (broken) Excel sheets and to master super urgent jobs.

Made with by NETRONIC Software GmbH (Copyright © 2019) Read our Privacy Policy & Terms of Service